Support for PLA – with spool – Bambu Lab

Features

- Effortless removal

- Save every detail

- Affordable choice

- Use for supporting interface

- Available with reusable main spool

- Diameter: 1.75 mm +/- 0.05 mm

- 500 g.

Warnings for use

-

- Used only for printing the maintenance interface

- Avoid printing individual patterns

- Compatible with AMS and AMS lite

Bambu Support for PLA

Bambu’s PLA support is fully compatible with all Bambu Lab PLA filaments and Bambu Lab printers, offering seamless peel, smooth interface quality and reliable operation. It eliminates the need for post-processing, saving time while delivering flawless results. And all at a bargain price. Improve your 3D printing experience today!

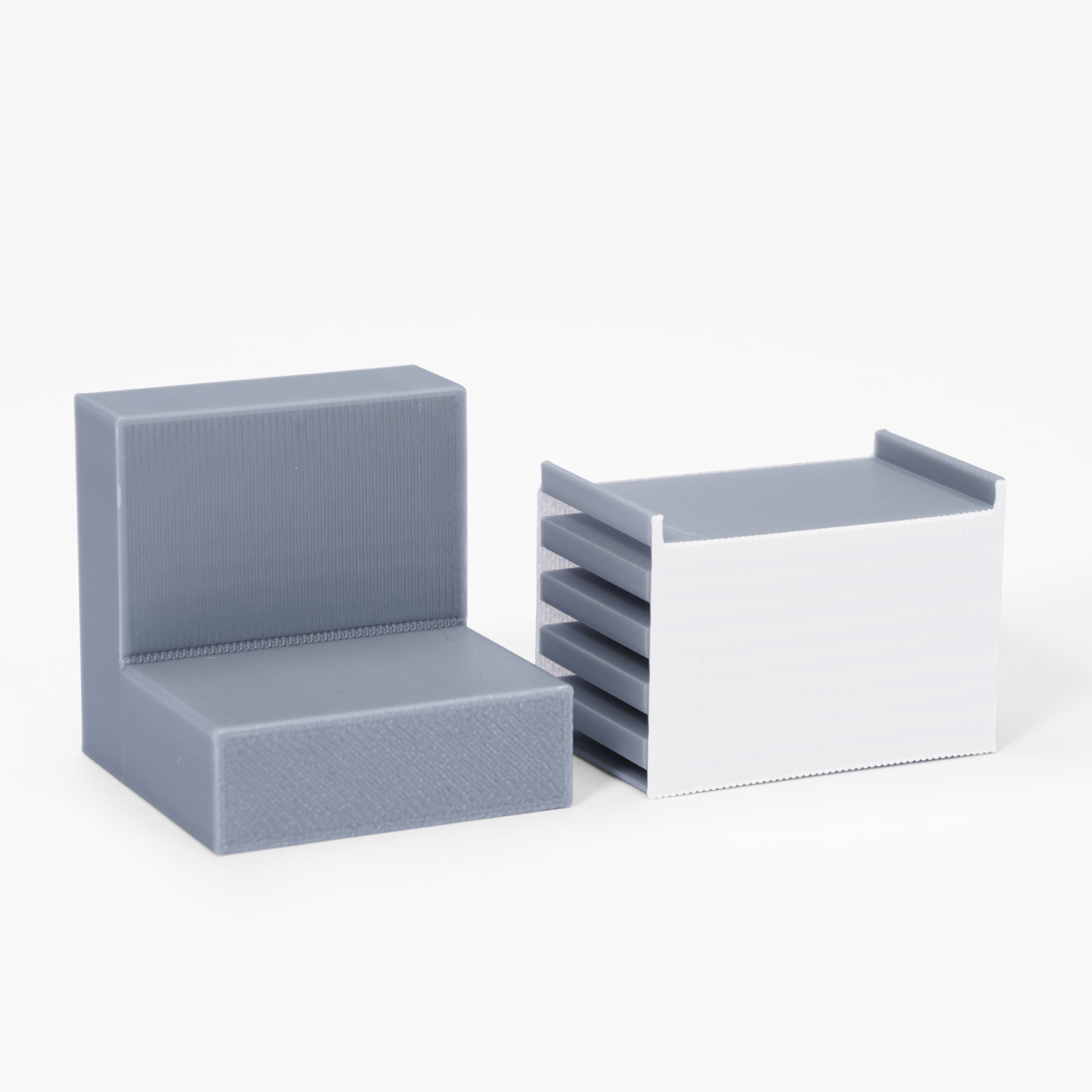

Effortless removal

The Bambu PLA pad is specially designed for PLA filaments, providing clean, residue-free removal by hand. Say goodbye to post-processing and enjoy hassle-free 3D printing.

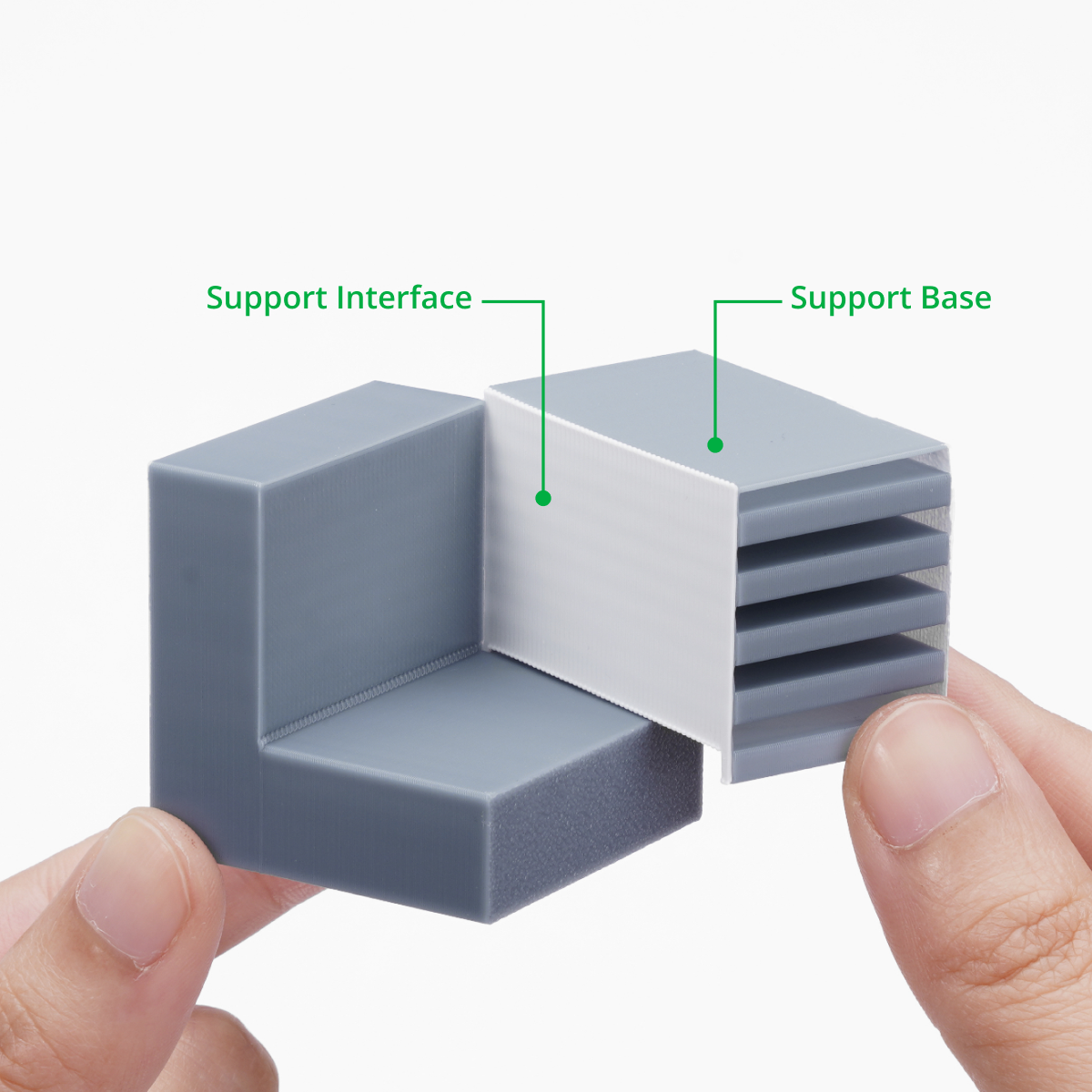

Save every detail

With optimized support interface settings* in Bambu Studio, Bambu Support for PLA provides an extremely smooth contact surface that protects intricate details as if they were untouched. Perfect for delicate designs, overhangs and bridges, it ensures premium quality from start to finish.

* 0 mm distance between the upper interface and 0 mm Z distance settings

Use for maintenance interface

Enable the “Support/craft interface” setting in Bambu Studio to apply the support material exclusively to the contact surfaces. This approach minimizes material usage, saving time and money.

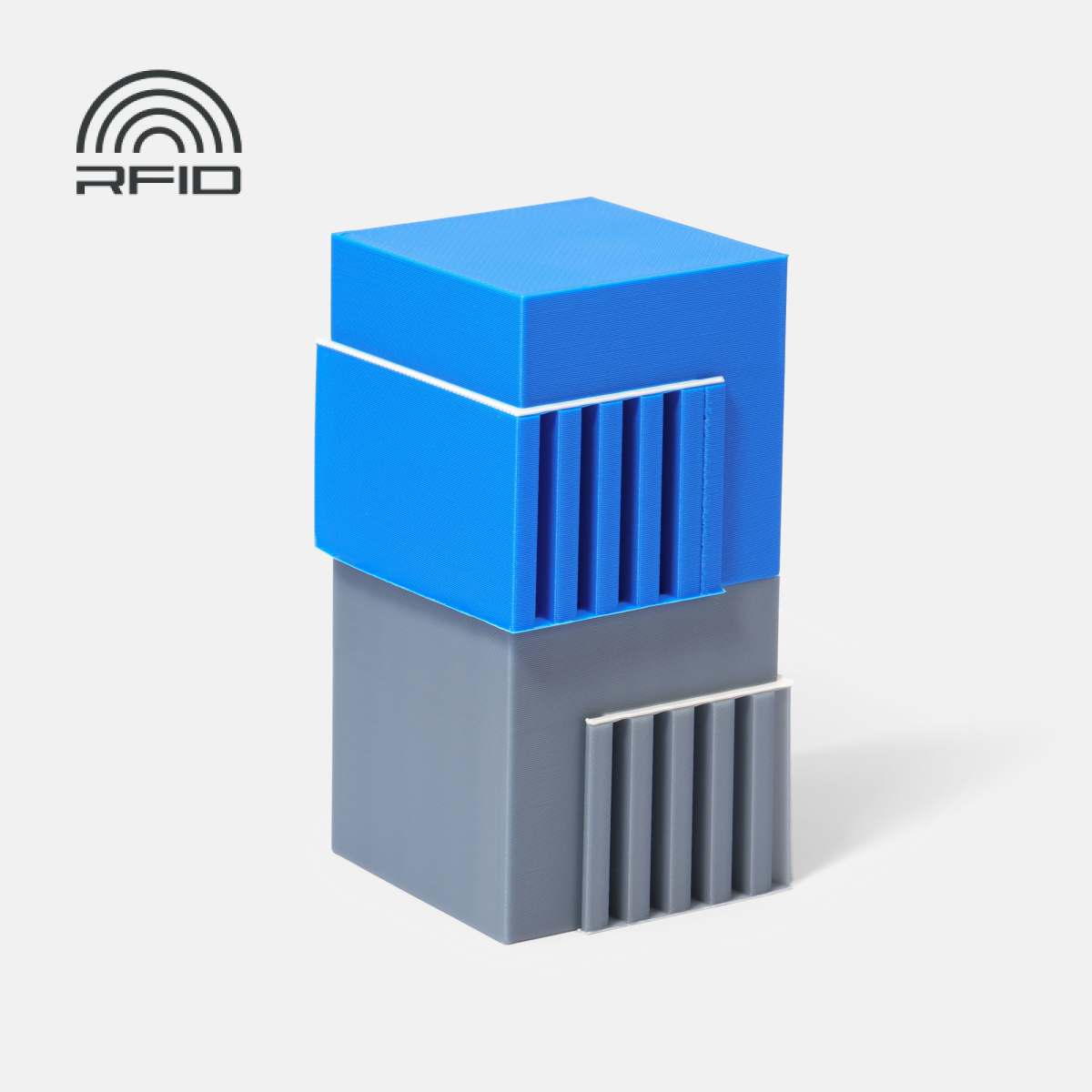

RFID for smart printing

All print parameters are embedded in the RFID, which can be read via our AMS (Automatic Material System).

Load and print! No more tedious setup steps.

Comparison of parameters

Learn more about the comparison of different threads in The Bambu Thread Guide >>

| Support for PLA/PETG | Support for PLA | Support for ABS | Support for PA/PET | PVA | |

| Colour: | Natural | White and Black | White | Green | Transparent |

| Nozzle type: | All sizes and materials | All sizes and materials | Hotend with hardened steel nozzle 0.4 mm/ 0.6 mm/ 0.8 mm Hotend with stainless steel nozzle 0.4 mm |

Hotend with hardened steel nozzle 0.4mm / 0.6mm (recommended) / 0.8mm | All sizes and materials |

| Nozzle temperature: | 190 – 220 °C | 220 – 230 °C | 240 – 270 °C | 280 – 300 °C | 220 – 250 °C |

| Bed temperature: | 35 – 60 °C | 35 – 45 °C | 80 – 100 °C | 80 – 100 °C | 35 – 45 °C |

| Print speed: | < 100 mm/s | < 200 mm/s | < 100 mm/s | < 100 mm/s | < 200 mm/s |

| Solubility: | Water Soluble | Water Soluble | Water soluble, Soluble in citric acid | Water Soluble | Water Soluble |

| Drying before use: | Optional | Optional | Optional | Required | Required |

| Dry protection during use: | Optional | Optional | Optional | Required | Required |

| Filament compatibility: | PLA, PETG | PLA | ABS | PAHT-CF,PA6-CF,PA6-GF, PET-CF | PLA, PETG |

Compatibility of accessories

| Recommended : |

Not recommended : | |

| Backing: |

Cool pad SuperTack, Smooth PEI pad , Textured PEI pad

|

/ |

| Hotend: |

All sizes and materials | / |

| Bambu liquid glue / glue stick / EcoFixy glue | Bambu liquid glue / glue stick / EcoFixy glue | / |

| Recommended print settings : | |

| Drying settings (shock drying oven): | 55 °C, 8 h. |

| Printing and maintaining the humidity of the container: | < 20% RH (Sealed, with desiccant) |

| Nozzle temperature: | 220 – 230 °C |

| Bed temperature (with adhesive) | 35 – 45 °C |

| Print speed: | < 200 mm/s |

| Physical properties : | |

| Density: | 1.33 g/cm³ |

| Vicat softening temperature: | N/A |

| Heat deflection temperature: | N/A |

| Melting temperature: | 190 °C |

| Melting index: | 13.6 ± 1.2 g/10 min. |

| Mechanical properties: | |

| Tensile strength: | N/A |

| Fracture extension rate: | N/A |

| Bending module: | N/A |

| Bending force: | N/A |

| Impact Force: | N/A |

Printing tips

– For large flat surfaces, use the “Normal” support type with the “Default” style for optimum results. For complex patterns, select the “wood” support type with the “Hybrid Wood” style. For more details, visit ” Support” on WIKI.

– It is recommended to dry the maintenance filament before printing and keep it enclosed in the AMS with a desiccant throughout the printing process to optimize print quality.

– Drying conditions:

In a shock dryer: 55°C for 8 hours.

On the heat bed of the X1 printer and the H2D printer: 65°C to 75°C for 12 hours.

AMS 2 Pro and AMS HT: 60°C for 12 hours.

– For more filament drying settings , please see Filament Drying Recommendations in WIKI.

What’s in the box?

There are no reviews yet.