Support for PLA / PETG – with spool – Natural – Bambu Lab

Features

- Easy removal without tools

- Smooth interface support

- Recommended for all PLA and PETG

- Transparent appearance

- Comes with a high temperature reusable spool

- Diameter: 1.75 mm +/- 0.05 mm

- 500 g.

Warnings for use

-

- Used only for printing the maintenance interface

- Avoid printing individual patterns

- Compatible with AMS and AMS lite

Note: Before you start printing, please kindly refer to “Printing Tips for Optimum Results.”

Bambu Support for PLA/PETG

The best auxiliary material compatible with PLA and PETG filaments. Seamless tool-less removal while maintaining the pristine surface of the printed object.

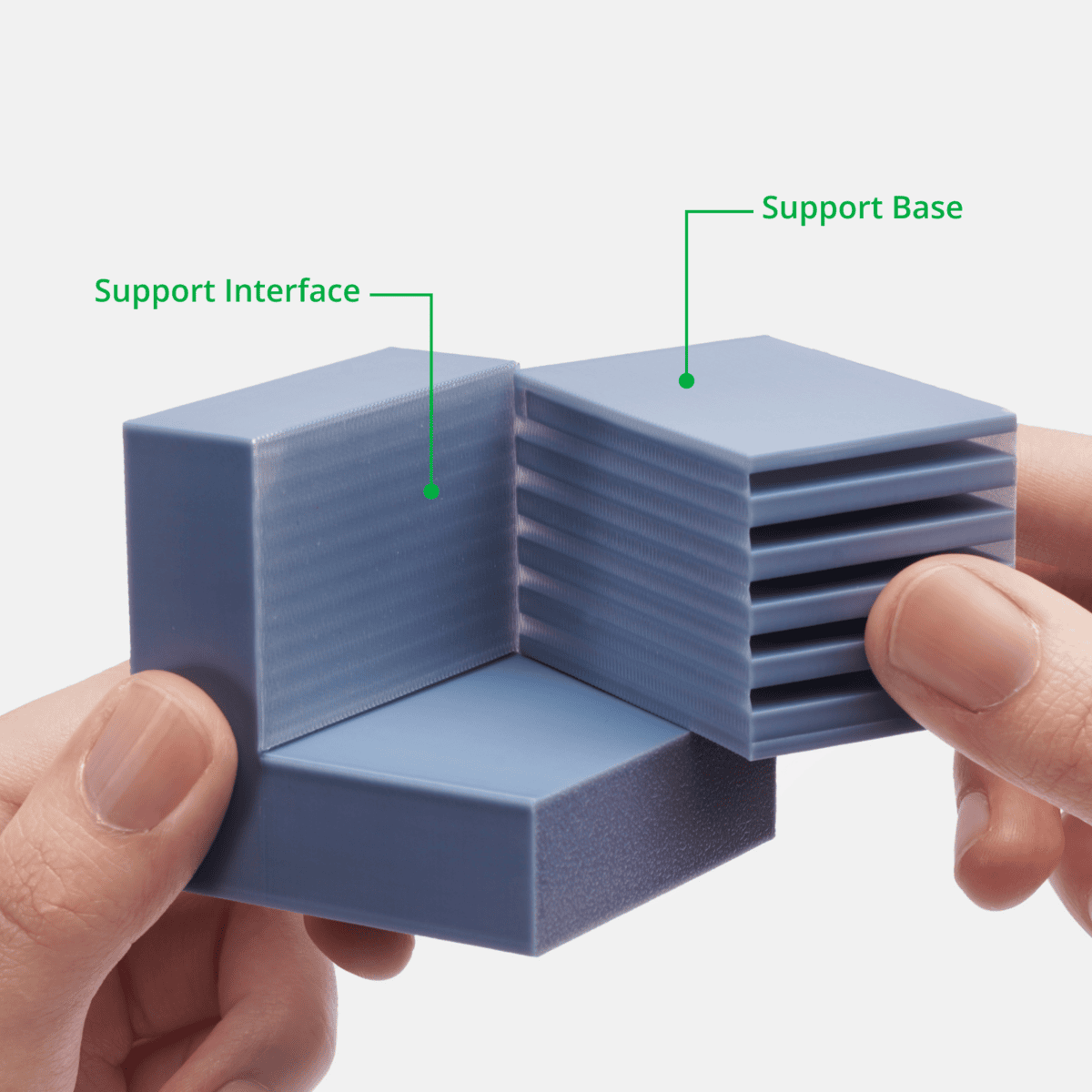

Easy removal without tools

The PLA/PETG support is specifically designed to minimize fusion with PLA and PETG due to differences in polarity. This unique feature ensures seamless removal of the support interface, reducing the risk of damage to your printed object.

Smooth maintenance interface

The PLA/PETG support interface offers a consistently smooth surface in the contact area, ensuring optimal support of complex workpieces. With zero distance between the top of the interface and the Z distance, our support material provides precision and reliability, allowing you to print even the most complex designs with ease.

Cross Compatibility

The PLA/PETG support material is designed for seamless use with both PLA and PETG, eliminating the need to change support materials. This allows you to save time and simplify your workflow.

Comparison of parameters

Learn more about the comparison of different threads in the Bambu Thread Guide >>

| Support for PLA/PETG | Support for PLA | Support for ABS | Support for PA/PET | PVA | |

| Colour: | Natural | White and Black | White | Green | Transparent |

| Nozzle type: | All sizes and materials | All sizes and materials | Hotend with hardened steel nozzle 0.4 mm/ 0.6 mm/ 0.8 mm Hotend with stainless steel nozzle 0.4 mm |

Hotend with hardened steel nozzle 0.4mm / 0.6mm (recommended) / 0.8mm | All sizes and materials |

| Nozzle temperature: | 190 – 220 °C | 220 – 230 °C | 240 – 270 °C | 280 – 300 °C | 220 – 250 °C |

| Bed temperature: | 35 – 60 °C | 35 – 45 °C | 80 – 100 °C | 80 – 100 °C | 35 – 45 °C |

| Print speed: | < 100 mm/s | < 200 mm/s | < 100 mm/s | < 100 mm/s | < 200 mm/s |

| Solubility: | Water Soluble | Water Soluble | Water soluble, Soluble in citric acid | Water Soluble | Water Soluble |

| Drying before use: | Optional | Optional | Optional | Required | Required |

| Dry protection during use: | Optional | Optional | Optional | Required | Required |

| Filament compatibility: | PLA, PETG | PLA | ABS | PAHT-CF,PA6-CF,PA6-GF, PET-CF | PLA, PETG |

Compatibility of accessories

| Recommended : |

Not recommended : |

|

| Backing: | Cool SuperTack pad, Smooth PEI pad, Textured PEI pad | / |

| Hotend: | All sizes and materials | / |

| Bambu liquid glue / glue stick / EcoFixy glue | Bambu liquid glue / glue stick / EcoFixy glue | / |

RFID for smart printing

All print parameters are embedded in the RFID, which can be read via our AMS (Automatic Material System).

Load and print! No more tedious setup steps.

| Recommended print settings: | |

| Drying settings (shock drying oven) : | 75 °C, 8 hrs. |

| Printing and maintaining the humidity of the container: | < 20% RH (Sealed, with desiccant) |

| Nozzle temperature: | 190 – 220 °C |

| Bed temperature (with adhesive): | 35 – 60 °C |

| Print speed: | < 100 mm/s |

| Physical properties: | |

| Density: | 1.28 g/cm³ |

| Vicat softening temperature | N/A |

| Heat deflection temperature: | N/A |

| Melting temperature: | 185 °C |

| Melting index: | 14.3 ± 1.2 g/10 min. |

| Mechanical properties: | |

| Tensile strength: | N/A |

| Fracture extension rate: | N/A |

| Bending module: | N/A |

| Bending force: | N/A |

| Impact Force: | N/A |

Printing tips

– Recommended for use with PLA or PETG filaments only. Select “Support for PLA/PETG” (Support for PLA/PETG) in the “Support/Raft Interface” settings in your slicer.

– When using tree supports, please avoid using support filament for the “”Support/raft base””.

– Store the filament in a dry place, and if it is fragile or exposed to moisture, dry it at 75°C for 8 hours (see WIKI’s Filament Drying Guide: Filament Drying Instructions).

– For more settings related to maintenance, please see Maintenance in WIKI.

What’s in the box?

There are no reviews yet.