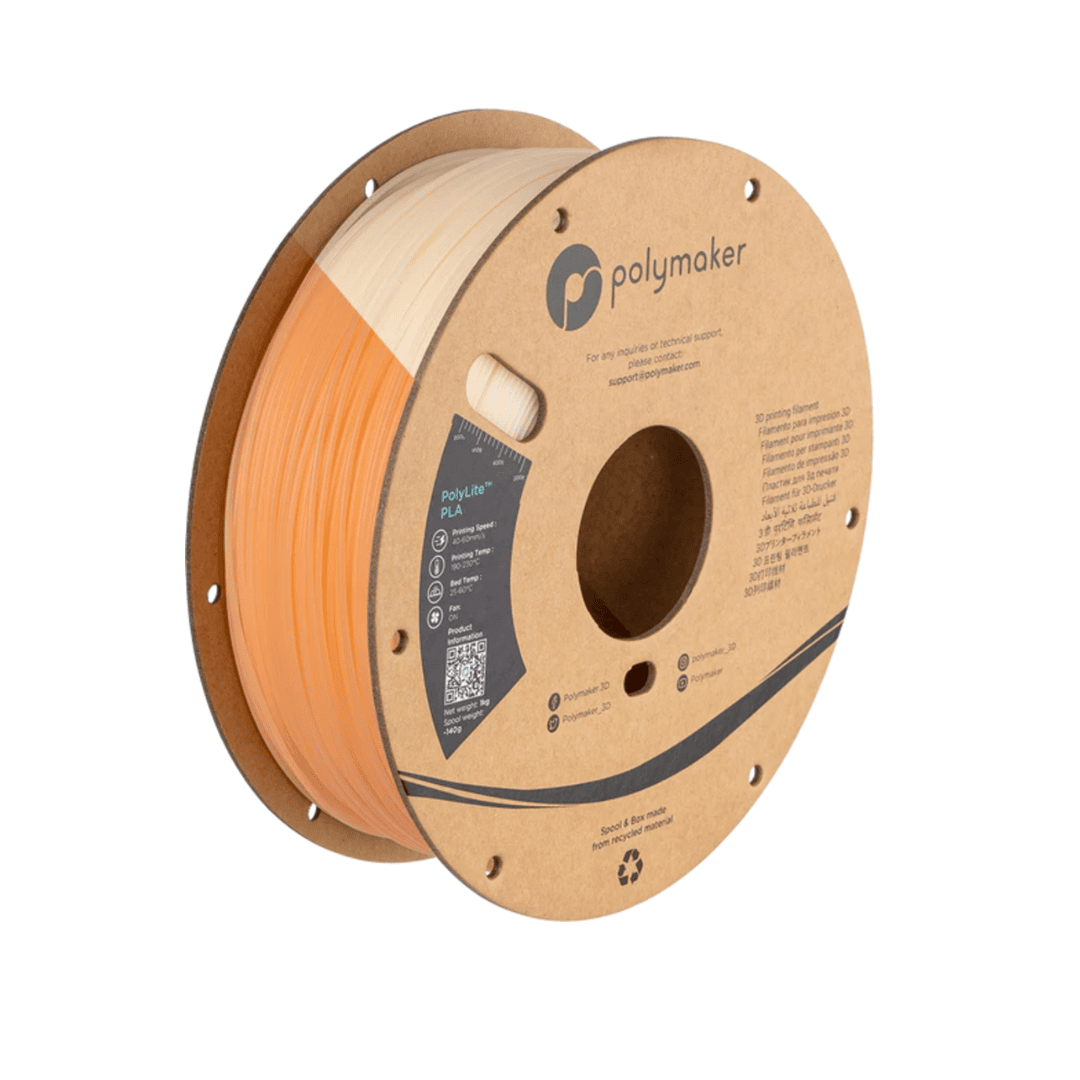

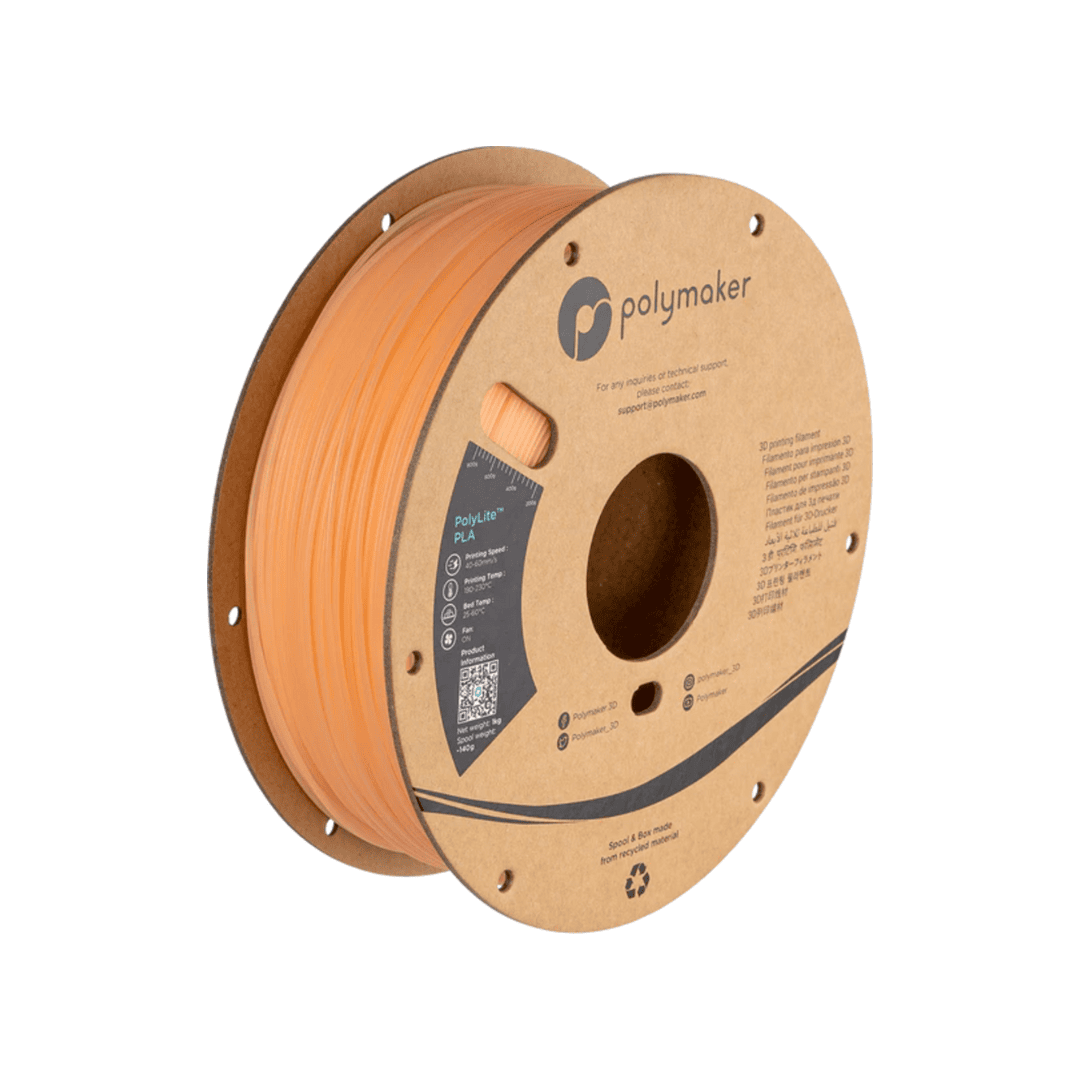

PolyLite PLA – UV color changing from natural to orange- Polymaker

Features

- Easy to print

- Polymaker quality

- Changing colour according to UV light

- 1kg

- PolyLite PLA

Polymaker’s PolyLite PLA is an easy-to-print, high-quality PLA filament based on high molecular weight PLA from Natureworks. The material features high stability and reliability; thanks to Polymaker’s Jam-Free technology, the filament’s heat resistance is also increased.

Colour change to UV light

This unique PLA with a magical color changing effect changes color depending on the UV light. The material adds visual dynamism to your creations, turning temperature into an artist’s chameleon.

Properties

- Strength and stiffness – PolyLite™ PLA is based on high molecular weight PLA from Natureworks, making it one of the stiffest PLA materials on the market. The combination of good tensile strength, interlayer adhesion and stiffness makes PolyLite™ PLA ideal for product design and prototyping applications that require a rigid material that is easy to print.

- Compatibility – PolyLite™ PLA is a high-quality PLA filament compatible with a wide range of 3D printers including models from Bambu Lab , Creality, FlashForge, Monoprice, Lulzbot, Makerbot, Ultimaker, Prusa Research, Raise3D, Tiertime and other popular extrusion-based 3D printers. PolyLite™ PLA can be printed without a heated bed and works well with conventional print surfaces, although a heated bed (60°C maximum) can be used for better results.

- Jam-Free™ Technology – PolyLite™ PLA is manufactured with Polymakers’ Jam-Free™ technology, which improves the thermal stability of filament with a softening temperature of over 140°C and results in excellent print quality with zero risk of nozzle clogging caused by thermal creep.

- Uncompromising quality – PolyLite™ PLA filament is manufactured with the highest quality ingredients, including Ingeo® from Natureworks. Natureworks is a leading US-based global supplier of biopolymers with a portfolio of high-quality PLA feedstocks made from rapidly renewable plant resources. Combining Polymakers’ innovative R&D technologies, blending and extrusion systems with Natureworks’ Ingeo® resins yields a reliable 3D printing filament that prints beautiful and accurate models.

Thermal creep is the process of heat spreading unevenly across a hot end, a common example being in all metal hot end structures. Once the heat creeps to the cold end, the PLA filament softens prematurely at the cold end and expands, causing a jam. Polymakers’ Jam-Free™ technology increases the heat resistance of the filament itself (not the printed part) to 140˚C, which prevents the filament from softening prematurely at the cold end and yet can still melt quickly once it enters the heating zone.

Settings when printing

| Nozzle temperature: | 190°C – 230°C |

|---|---|

| Pad Temperature: | 25°C – 60°C |

| Substrate Material: | Works well with most building surfaces, e.g. glass, masking tape, BuildTak®, etc. |

| Surface treatment | You can apply EcoFixy , Magigoo Original or PVA adhesive to the build surface to improve adhesion. |

| Cooling fan: | ON |

| Print speed: | 40 mm/s – 60 mm/s |

| Recommended support material: | Single extrusion:

Self-support Double extrusion: PolyDissolve™ S1 (dissolves in tap water) PolySupport™ for PLA (Easily peelable support material) |

The above printing recommendations are based on a 0.4 mm nozzle. Please note that ideal printing conditions may vary depending on your 3D printer settings. For high-speed 3D printers, be sure to increase the extrusion temperature to use higher print speeds.

For other printing tips on PolyLite™ PLA contact us!

Specifications

| Net weight: | 1kg. |

|---|---|

| Type of material: | PLA |

| Density: | 1.17 (g/cm3 at 21.5˚C) |

| Technology: | Features Jam-Free™ technology |

Compatibility

PolyLite™ PLA has been developed with compatibility in mind to print perfectly on a wide range of 3D printers. The Jam-Free™ technology incorporated into PolyLite™ PLA can improve compatibility with all metal hosts that suffer from thermal creep.

High rigidity materials such as PolyLite™ PLA work best in kits where the filament guide system is smooth and there are no sharp bends.

Of course, with thousands of unique 3D printer models on the market, we can’t guarantee that every type of filament will work with every 3D printer. Experience with cutting tools and adjusting settings is always required to get the most out of a material. Before embarking on an ambitious project, we always recommend printing some known calibration tests to build or make adjustments to the filament profile.

Technical data

All test specimens were printed under the following conditions: nozzle temperature = 205˚C, build plate temperature = 45˚C, leachate = 100%, cooling fan = on.

All specimens were conditioned at room temperature for 24 hours prior to testing.

Thermal properties

| Value | Method of testing |

|

| Glass transition | 61°C | DSC, 10°C/min |

| Heat deviation temperature | 0.45MPa – 59.8°C 1.8 MPa – 58.1°CHDTCurve |

ISO 75 |

| Vicat softening temperature | 62.9°C | ISO 306, GB/T 1633 |

Mechanical properties

| Value | Method of testing |

|

| Jung’s module (X-Y) |

3,426.9 MPa | ISO 527, GB/T 1040 |

| Tensile strength (X-Y) |

52.3 MPa | ISO 527, GB/T 1040 |

| Bending force (X-Y) |

86.9 MPa | ISO 178, GB/T 9341 |

| Sharpey impact strength (X-Y) |

3.3 kJ/m2 | ISO 179, GB/T 1043 |

The typical values presented in the Polymaker data sheet are for reference and comparison only. Due to the nature of 3D printing, they should not be used for design specification or quality control purposes.

Storage and drying

All plastics are hygroscopic, meaning they absorb moisture from the air, which can affect the print quality and strength of printed parts. How quickly this absorption occurs depends on the material and the environment. Polymakers PolyLite™ PLA fibers are dried and packaged in a vacuum bag with desiccant to ensure the best print quality. When not in use, PolyLite™ PLA should be stored away from sunlight and sealed in the packaged resealable bag.

Although the strands can be dried, drying will accelerate the aging process of the plastic, making it more brittle over time. Preventing moisture from being absorbed by the filament in the first place is the best solution to keep your filament working to its maximum potential. For long-term storage, we highly recommend storing in a sealed container with a desiccant dryer that reduces relative humidity to 10-20% RH.

Here at Polymakers, we manage our filaments with Polymakers PolyDryer™, which offers best-in-class sealing to keep filaments from absorbing moisture

If you hear popping sounds and notice that the surface quality of your print is uneven or the color is not consistent, this is a likely indicator that the filament has absorbed too much moisture. PolyLite™ PLA spools can be dried with Polymaker PolyDryer™ using power level 1. Alternatively, if you have a convection oven that is accurate at low temperatures, users can dry the filament in a pre-heated convection oven at 55˚C for up to 6 hours. Results may vary depending on the accuracy of your oven, so please use caution.

Frequently Asked Questions

Q: Does Jam-Free™ technology prevent any jamming of the thread?

A: Jam-Free™ technology is designed to prevent clogging caused by thermal creep. There are many reasons why a material can jam, such as a partially blocked nozzle, printing at the wrong extruder temperature, or incorrect nozzle height; Polymaker’s Jam-Free™ technology will not prevent jamming in these cases.

Q: Is PolyLite™ PLA a PLA+ material?

A: PolyLite™ PLA is a PLA material rather than PLA+, and it is important to keep in mind that PolyLite™ PLA is actually stronger than many PLA+ materials. Unlike PLA+, which contains additives to improve specific mechanical properties, the high strength of PolyLite™ PLA is a result of the natural raw material chosen. Typically PLA is characterized by low impact strength but offers very high tensile strength /and stiffness. PLA+ materials typically sacrifice tensile strength to offer improved impact resistance. If you are looking for a PLA+ or material with improved impact resistance, we recommend PolyLite™ PLA Pro or PolyMax PLA. PolyLite™ PLA Pro is a PLA+ formulated to maintain the stiffness and high strength of PolyLite™ PLA while significantly improving impact resistance. PolyMax™ PLA is a rigid and resilient PLA+ formulated to mimic the mechanical properties of ABS.

Q: What auxiliary materials can I use with this product?

A: If your 3D printer supports multi-material 3D printing, PolyLite™ PLA is compatible with Polymaker’s PolySupport™ and PolyDissolve™ S1 filaments. PolySupport™ is a peelable support material that can be easily peeled off, and PolyDissolve™ S1 is a water dissolvable support material ideal for complex geometries.

Q: Do I need to rewind this thread if I want to use it with another spool?

A: We strongly advise you not to manipulate the product by rewinding. All Polymaker filaments are wound with tension, but without straining. Rewinding completely rearranges the curvature of the coil and this tension over time can cause most plastics to catastrophically break. If for some reason your printer is blocked from mounting smaller than standard size spools, there may be safe print adapters or external mounting solutions available.

Don’t know where to start? Or which thread would be right for your application? Contact us today!

Applications

PolyLite™ PLA is a popular choice for beginners and experts alike who need a cost-effective, reliable and easy-to-use PLA filament. This is one of our recommendations for users who are relatively new to 3D printing and looking for a reliable material to get started.

Typically used to print a wide range of common print projects including:

- Trifles.

- Toys.

- Housewares.

- Prototypes.

- Cosplay elements.

- Staples and production aids.

- Scale models and architectural models.

- Anatomical and educational models.

Compared to other brands of plain PLA, PolyLite™ PLA has particularly high strength (tensile) and stiffness (Youngs modulus), making it a good choice for functional applications that are not subject to high temperatures, drops or impacts, but require high stiffness and interlaminar adhesion. For applications that require PLA that offers high impact strength and high stiffness, we recommend considering PolyLite™ PLA Pro.

The stiffness of PolyLite™ PLA is quite high, so less rigid and more flexible Polymaker PLA may be ideal for models that require some flexibility, such as snap-fit housings. For such applications, we recommend considering PolyMax™ PLA, which features excellent impact strength, fracture toughness, ductility and with similar strength and stiffness to ABS.

Polymaker is an international team that is passionate about 3D printing. They produce the finest 3D printing materials, controlling every stage of production. With a diverse portfolio of materials ranging from high-performance plastics to unique aesthetic solutions, Polymaker will continue to add cutting-edge materials to their ever-growing portfolio.

At the heart of Polymaker is their research and development lab, where all Polymaker materials are formulated and refined from scratch to create best-in-class 3D printing materials. Their precision testing equipment combines the latest advances in technology to ensure they are ahead of the game.

High-quality raw materials are critical to producing consistent and reliable filaments, which is why Polymaker has partnered with NatureWorks and uses Ingeo PLA resins as the main ingredient of PolyLite™ PLA. Polymaker’s innovative R&D technology, blending and extrusion systems combined with Natureworks’ Ingeo resins produce a reliable 3D printing filament.

Today, NatureWorks is a leading global supplier and innovator in biopolymers with its Ingeo portfolio of naturally advanced materials made from renewable and widely available raw materials that rival intermediates, plastics and petroleum-based fibers in performance and cost-effectiveness.

PolyLite™ PLA, like all other Polymaker materials, is manufactured using state-of-the-art polymer processing technology and equipment. Polymaker’s rigorous quality control processes ensure industry standards for reliability to ensure consistent customer performance.

Tolerance – Polymakers’ custom-developed extrusion, control and monitoring solutions ensure that filament tolerance and roundness meet Polymakers’ stringent quality standards.

Reliable mechanical, coloring and printing properties – Each batch of filament products is tested to ensure that all quality specifications (melt flow, softening point, mechanical, diameter, roundness) are met.

Drying and Vacuum Sealing – Prior to packaging, all Polymaker filaments are dried to a < 0.1% moisture level to ensure the best print quality, and vacuum sealed to protect the filaments from moisture. All vacuum packed products are allowed to sit for 24 hours before being boxed to ensure they do not leak.

There are no reviews yet.