Silk Refill – Gold – Azurefilm

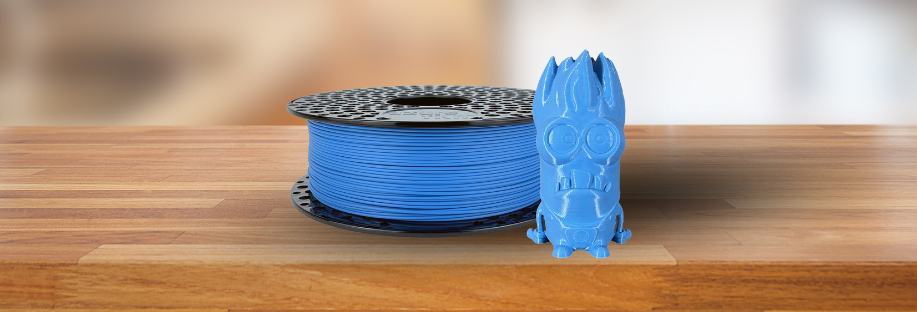

Refill PLA Silk

PLA Silk Refill filaments offer the same properties as our PLA Silk. They give your prints a glossy, slightly transparent and silky surface. Additionally, this material helps to hide transitions between layers when printing.

Refill PLA Silk is easy to print and comes in many different colors. These filaments are an eco-friendly choice that offers reliable performance and consistent results. Plus, our Refill PLA Silk filaments are perfect for beginners.

What is new?

- We removed the plastic cable ties and replaced them with a better option to make unpacking easier.

- The end of the filament is now completely right. This prevents it from getting stuck in the spool and damaging the print when the filament runs out.

- Perfect compatibility with AzureFilm and Bambu Lab reels.

Print Recommendations:

- For best results, print at 220-240 °C.

- The recommended substrate temperature for printing is 80 °C.

- Use glass backing, PEI sheet, Kapton or blue tape for the build platform with 3Dlac spray or EcoFixy adhesive.

*Ideal temperature may vary when using different printers.

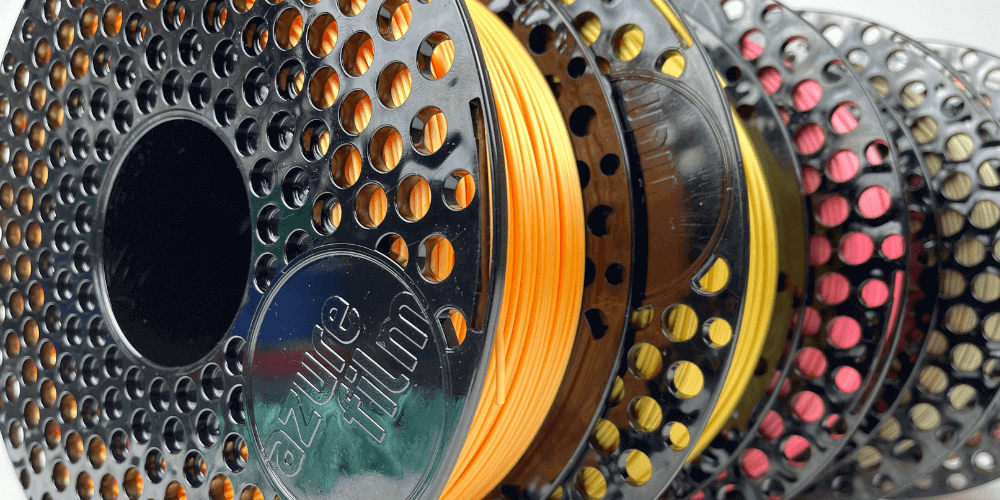

Our Refill PLA Silk Filaments are fully compatible with the AzureFilm Master Spool – the only spool you’ll need. By using this reusable spool, you can join us in reducing waste and minimizing environmental impact.

The AzureFilm Master Spool is our reusable spool that offers a sustainable and economical solution for 3D printing. The spool is a set of two reusable, injection molded disks. This ensures high durability and roll precision.

By purchasing and reusing our Master Spool, you are contributing to a cleaner environment while enjoying a reliable and easy-to-use product compatible with most 3D printers.

Characteristics and properties

| Feature | Value |

|---|---|

| Flexibility: | Low |

| Strength: | Medium |

| Durability: | Medium |

| Hard to print: | Low |

| Shrinkage / Distortion | Minimum |

| Solubility: | NO |

| Diameter: | 1.75mm |

| Manufacturer: | AzureFilm |

PLA filaments: everything you need to know!

PLA is one of the most used filaments for 3D printers, known for its wide color range, versatility and style. It is therefore suitable for many printing applications. Those who want high-quality, vibrant and aesthetic 3D prints often use PLA filaments.

PLA (polylactic acid) filaments are very easy to use and are ideal for beginners to experiment with. But what makes it one of the best filaments for 3D printing?

What are PLA filaments?

PLA is an environmentally friendly 3D printing filament derived from organic sources. The raw material used here is corn starch from sugar cane and the like. The manufacturing process of this thermoplastic monomer is what sets it apart from other 3D printing filaments.

Producers use biomass resources to produce PLA filaments. You can use the equipment used to produce petrochemical plastics to produce PLA filaments . In this aspect, the difference in raw materials does not matter. And it does not increase the production cost either, which is a big plus.

PLA is environmentally friendly as it is biodegradable, needs 65% less energy compared to the production of conventional plastics, and is solvent weldable. It also has no toxins and emits 68% less greenhouse gases.

How are PLA filaments produced?

Fermented starch from plants such as maize, sugar cane or cassava is used to produce PLA filaments. Fermentation of the raw materials converts them into lactic acid, from which PLA is obtained. Manufacturers typically use two methods to produce PLA filaments.

1. Polymerization

2. Condensation

In the polymerization method, you will need metal catalysts. And to make large PLA molecules, mix lactide with metal catalysts. The condensation method is not much different than the polymerization method. The byproducts and temperature are slightly different from the former process.

You can also produce broad-spectrum blends of PLA filaments by mixing materials such as copper, bamboo, pine, cedar, bronze, carbon fiber, etc.

Mixing wood with PLA filaments makes 3D printed furniture more realistic. If you want to give the printed parts a shiny look, combine metal with PLA. This will also make the print sturdy.

How to print with PLA filaments?

Bambu Lab , Creality Ender, FlashForge and Artillery are some of the 3D printers that are most compatible with PLA materials. There are a few things to keep in mind while printing with PLA filaments , viz:

- Temperature

To ensure the best printing result, you should be more interested in the temperature of the hotend and nozzle than the bed temperature. When the temperature is high, the interlayer bonding of your print becomes large. High temperature means faster printing and better material flow.

But too high a temperature rise can affect the seal by deforming some of the parts of the seal. Too high a temperature melts the extruded layers excessively and this can cause the print to sag or bleed.

For best results, the printing temperature should be varied between 200-230 °C while printing with PLA filaments. In addition, the ideal temperature can also vary depending on the nozzle size and printing speed. So do some experimental prints to find the best temperature for your 3D printer.

- Bed adhesion

Good bed adhesion is very important when printing with PLA or other filaments. Bed adhesion refers to the ability of the printed plastic to remain attached to the substrate as long as the printing process lasts.

To improve the adhesion of the printer bed, you can do the following:

- Wipe the print bed with isopropyl alcohol before printing.

- Apply bed adhesives such as hairspray or glue (EcoFixy glue is best).

- Adjusting the temperature of the bed is a good option to increase adhesion. For PLA, keep the bed temperature to 60 °C for better adhesion.

- Improper alignment may be the cause of poor bed traction. So before you start printing, check whether the bed is level or not.

- Printing too fast can displace the plastic print, so slowing down should do the trick.

- Changing the surface of the bed is another great option for increasing bed traction if the above methods don’t work.

Some of the well-liked options of the PLA filament printing bed surface are:

- Blue ribbon:

This is a type of masking tape. It is used to cover the seal bed to improve adhesion. These tapes are usually porous, which is ideal for filaments such as PLA. The best blue tapes designed to improve print bed adhesion are heat resistant.

- Thermal tape

These ribbons work as a base layer and protect the print bed surface. You should use glue, hairspray or similar products to adhere them. The best thing about these tapes is that they come in large rolls. Thus, one sheet is enough for the surface of the bed. But be very careful when spreading the thermal tape on the bed. Air bubbles can get under the tape and create wrinkles.

- PEI

PEI sheets, or directly PEI pads , are great for printing with different filaments. With them, you won’t need adhesive sprays, clips or adhesives, nor surface preparation for printing.

- Glass bed

A glass bed is another excellent bed surface alternative that you can consider. Glass beds are strong, dense and durable. We recommend that you get a carborundum glass bed. Carborundum glass with a thickness of 3-4 mm can withstand heat from 150 to 400 degrees.

- Print speed

The printing speed must be above 50 mm/s when printing with PLA filaments. You can produce top-level aesthetic models if the print speed is close to 100 mm/s. But high-speed printing can deform PLA. That’s why you should run tests using different print speeds. This will help you find the right print speed for your printer and filament. When printing with PLA filaments, it is ideal to print slower to ensure optimal results.

To print complex models with details, you need to reduce the print speed. In case you are printing a simple pattern, it is better to increase the speed. Increase the extrusion speed for faster printing. You can also use the print head acceleration counter to increase the speed.

- Pre-grinding

In this process you need sandpaper, pliers, tweezers and a toothbrush to smooth the surface of the impression.

- Grinding

As the name suggests, you will need sandpaper in this post-processing stage. Buy 120 grit PLA filament sandpaper and do not use it on the corners or edges of the print pattern. Smoothing is done to correct the deformation of the prints, thus it can take a long time. The larger the print, the longer the sanding will take.

- Smoothing

Smoothing is really important to give your prints a shiny finish, and sanding alone can’t do that. Smoothing removes layer lines better than sanding. There are many smoothing techniques you can use, but here we’ll talk about chemical smoothing.

Chemicals such as ethyl acetate are a good option for smoothing PLA filaments. This chemical will dissolve the ply lines without manual labor. Additionally, using the chemical does not damage the layers underneath.

- Painting

In this process you will need two things, one is a spray stamp and the other is painter’s tape. The tape will hold the print firmly in place when you spray the paint. Spray paints come in bright colors and blend very well with the plastic.

Post-processing considerations

Post-processing is very important to improve the appearance of the print, its durability and functionality. Therefore, you should be careful with this process. Following are some of the post-processing considerations to keep in mind for a better print finish:

- Post-processing techniques such as pre-sanding, grinding or smoothing can alter the dimensional accuracy of the 3D print. And to maintain dimensional accuracy, make sure you have certain software, calipers, gauges, or micrometers.

- Designing prints in subassemblies allows for better smoothing. This way you can work on smoothing each part individually.

- We recommend painting your 3D prints in a controlled environment. This eliminates the possibility of any contamination that may affect the paint.

- To avoid drips and gaps, do not spray on your PLA 3D prints at close range. Spraying from too far away can create the same problem, so find the “sweet spot” that will produce optimal results.

- Make sure your 3D print is in an upright position before painting it.

- Wear appropriate clothing, masks and gloves for safety before spraying on your 3D prints. These paints are often toxic, flammable and risky.

Advanced tips and troubleshooting for printing with PLA filaments

- The temperature is too low for printing

If the temperature is not suitable, the PLA filaments will not stick, resulting in a rough surface. This can also make a part weak. Correct this problem by increasing the temperature by 5°C. Now try printing until you see that the layers are adhering properly.

- The temperature is too high to print

Excessive stringing means the temperature is too high for printing. In terms of PLA filaments, the more heat you use, the glossier the prints become. To avoid overshoots, get the best layer cooling system. Adjusting the printer’s retraction settings can help with threading. Reduce the temperature by 5°C if both methods do not work.

- If the first layer does not stick

This can happen if the bed surface is not level or the nozzle height is not suitable. Therefore, check these areas. If the spacing between the bed and nozzle is not correct, the PLA threads may drag. Also cause may be lack of glue , use EcoFixy glue for best results.

- If the printed parts have small bumps

This type of problem occurs when your printer is not receiving adequate data, your PLA filaments are bad, or your retraction settings are not set properly. Use your SDS card to troubleshoot this problem. Make sure you purchase the highest quality PLA filaments and check that the retract settings are correct.

PLA filament replacement

- Heat the extruder to 120°C if cold

- If the extruder temperature reaches 90°C, start removing all PLA filaments and raise the temperature to 200°C if there is a problem with PLA removal.

- Increase the temperature and fill the PLA filaments as usual.

- Now run the filament with the new color until you see nothing but the new color.

Common printing problems with PLA filaments

- Poor bed grip

PLA has absorbed too much water, leading to the extrusion problem. Drying the filaments will solve this problem. Use a filament dryer or a baking oven. Reducing the printing speed also helps. To avoid melting, keep the temperature lower than 50°C.

- Stringing

Filament breakage occurs when the extruder gets too hot or the retraction settings are incorrect. So check that the settings are correct and lower the temperature if the problem is in the extruder.

- Zits & Blobs

Enable the standby function to allow it to turn off the extruder for a bit. During this time the filament can cool down a bit for better printing. Also adjust the retraction settings to avoid Zits & Blobs.

- Deformation

Raising the bed temperature and using EcoFixy adhesive and enclosures should prevent warping. Adjusting the settings of the first layer and applying anti-deflection spacers can also help.

PLA fibres are very popular, making them the second most produced bioplastic. It is relatively inexpensive and easier to process. With the right print settings, PLA filaments can create quality prints.

Technical data

| Properties of 3D printed samples | Test condition | PLA |

| Tensile modulus [GPa] | 1 mm/min. | 3,3 |

| Tensile strength [MPa] | 50 mm/min. | 59,0 |

| Breaking strain (tensile) [%] | 50 mm/min. | 4,2 |

| Strain at tensile strength [%] | 50 mm/min. | 3,8 |

| Bending modulus [GPa] | 2 mm/min. | 2,8 |

| Flexural strength [MPa] | 2 mm/min. | 73,6 |

| Bending deflection at bending strength [%] | 2 mm/min. | 3,3 |

| Breaking (bending) strain [%] | 2 mm/min. | 3,3 |

| Sharps without chopping[kJ/m2] | 23 °C | 10,4 |

Settings for printing test samples:

- 3D Printer: Creality Ender 3

- Fill: 20%

- Nozzle temperature: 200 °C

- Slicer: Cura

- Sheathing: 2

- Bed temperature: 55 °C

- Nozzle: 0.4 mm

- Layer height: 0.2 mm

- Print speed: 50 mm/s

Print Recommendations:

- Nozzle temperature: 200 – 230°C

- Heated bed: not required (50-60 °C recommended)

- Print speed: 50-100 mm/s

There are no reviews yet.