PrimaCreator MK8 Ruby nozzle 0.4mm 1 pcs.

The PrimaCreator Ruby nozzle is the newest addition to the PrimaCreator nozzle range.

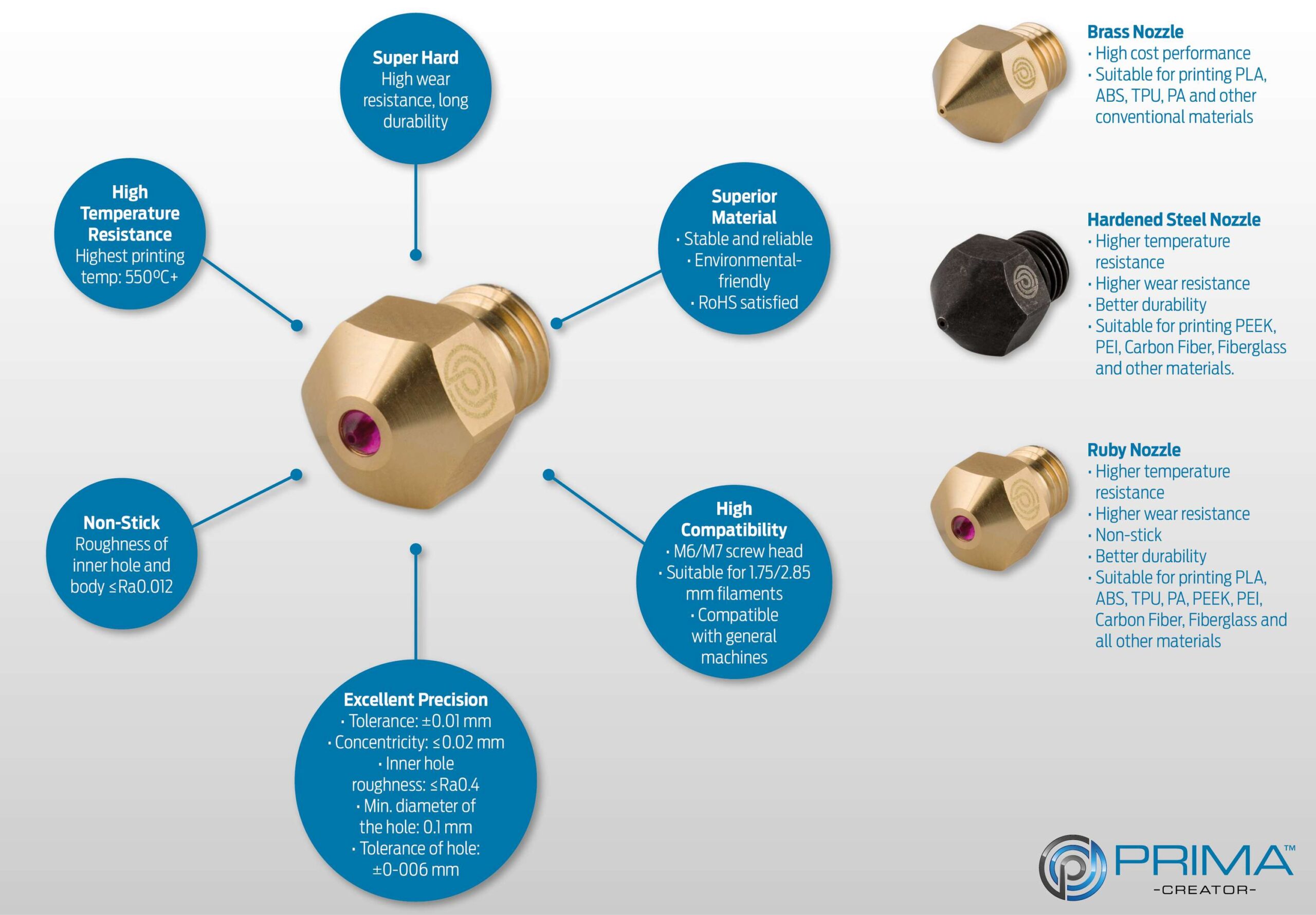

Plain brass nozzles are most often recommended as they have better conductivity when it comes to heat. But brass nozzles have their drawbacks. If you want to print with an abrasive material like carbon or glow-in-the-dark filament, a plain brass nozzle will wear out in a very short time. Therefore, you may choose to use a hardened steel nozzle, which will not wear out as quickly as a brass nozzle, but is made of steel and as a material is not optimized for use as an “everyday nozzle” due to the fact that the thermal conductivity is not as good as with a brass nozzle.

The most logical solution would be to get the best of both worlds.

Show off with the PrimaCreator Ruby nozzle.

In the best nozzle we have ever produced, we have the same high quality brass as in our regular nozzles, but in addition we have added a small ruby gemstone at the end of the nozzle. This turns a plain brass nozzle into a nozzle you can use with your standard filaments like PLA, ABS, PETG, etc., as well as more abrasive ones like carbon fiber filaments, glow in the dark metal, wood, well, with most types of “nozzle killer” filaments you can think of that are currently on the market.

Finally, you can use one nozzle for all your materials.

All ruby nozzles from PrimaCreator are made from the finest high quality brass with a genuine ruby tip. They are finished in the most modern factory. All nozzles are manufactured to a tolerance of less than ±0.01mm. This means your filament will have a very smooth and clean surface when extruded, which of course results in better prints.

For best results and optimal print quality, we highly recommend re-leveling your build plate after replacing the nozzle with a new one. Note that the Prima Creator nozzle may be compatible with your printer, but the distance between the nozzle and build plate must be adjusted.

The Prima Creator nozzle manufacturing process starts with a selected high quality material. When the material reaches the factory, an optical inspection is first made of the material to be used for each batch of nozzles. Then it’s time to press the material, in other words, turn it into a long rod. In our process this is only done once, and in many other (cheaper) cases this process has to be repeated several times, often as many as 3-4 times, and still the same results are not obtained.After this process the material is passed through an ultrasonic cleaning bath, then cleaned again and protected from surface oxidation.

The nozzle will now take shape with millimetre accuracy, with a tolerance of less than ±0.01mm.

The process of removing the sharp edges from the nozzles is a very important step as this makes up a large part of the result. If too many sharp edges are left on the nozzle, it will be more prone to clogging. Therefore, it is important that the nozzle is very smooth and clean before it is used. In each batch, a few nozzles are selected and cut in half to ensure that all specifications are met and that the surface is in perfect condition.

The nozzles are then checked one last time and packed individually in a protective box – ready to be shipped to you.

The Ruby Nozzle from PrimaCreator is the perfect choice for people who want only the best and at a great price!

Why should I use a ruby tip?

- All filaments, one nozzle

- Exceptional durability

- Perfect for many abrasive filaments such as carbon fiber, glow in the dark, fiberglass, metal, wood.

- Perfect diameter without serrated edges equals better print quality

There are no reviews yet.