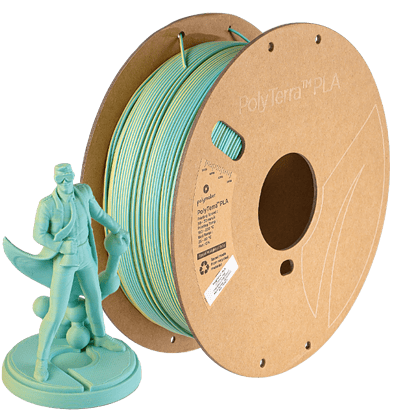

PolyTerra PLA – Turquoise + yellow – PolyMaker

Features

- Matte dichromatic/two-tone thread.

- Resistant Polymaker Matte PLA formula

- Smooth matt surface finish.

- Optimized for easier removal of the report.

- High speed capability with appropriate hardware.

- Excellent compatibility with printers.

- Consistent color and tolerance(1.75 mm diameter +/- 0.03 mm)

- This spool is suitable for the A1/X1 AMS system.

- 1kg

PolyTerra™ PLA Dual is a dichromatic matte PLA 3D printing filament that is produced in two different colors to give models a striking two-tone effect. Based on Polymakers PolyTerra™ Matte formula, this bioplastic filament is naturally sourced to provide ease of use, print quality, speed and reliability. It is the ideal choice for creating colour patterns with a smooth matt surface that hides the layers.

Properties

- Dichromatic Matte Finish – PolyTerra™ Dual PLA is a high-quality two-color matte finish that offers a beautiful and dynamic color transition effect for your 3D models providing a fun multi-color finish for hobbyists, educators and small businesses. Print details with a beautiful matte surface finish and unleash your imagination with Polymakers’ fun and dynamic two-color range.

- Optimized for spores- PolyTerra™ Dual PLA is designed with excellent spoor removal properties, allowing users to more easily tear spores or rafts from the surface of their prints.

- High-speed printing capability – Polymaker have developed the base formulation of PolyTerra™ PLA with ideal flow properties to provide a filament that is capable of high-speed printing (with appropriate hardware only).

- Bioplastic Mat PLA Formula – PolyTerra™ Dual PLA is based on a newly developed material from Polymaker called FBC (Fully Bio Compound). It is a compound of high quality Ingeo PLA supplemented with naturally occurring elements. The result is a PLA filament with less plastic content that feels softer and more flexible/less brittle on the spool. Polymakers FBC formula contains less PLA plastic to degrade, which improves the rate of degradation under specific industrial conditions. Like other PLAs, the degradation rate is still very slow at ambient temperatures.

- Ductility (X-Y) – PolyTerra™ Dual PLA is softer than conventional PLA, providing better ductility along the horizontal X-Y axis compared to standard PLA formulations. While a test strip of standard PLA will break in bending, PolyTerra™ Dual PLA will tend to gradually bend and break along the horizontal axis.

- Compatibility / Jam-Free™ – PolyTerra™ Dual PLA is compatible with a wide range of 3D printers and is manufactured using Polymakers Jam-Free™ technology, which results in excellent print quality with zero risk of nozzle jamming caused by thermal creep. PolyTerra™ Dual PLA works well on most printed surfaces with a thin layer of adhesive applied, no bed heating is required, but can sometimes be used at 40 – 50°C for better results (60°C maximum).

- Uncompromising quality – PolyTerra™ Dual PLA filament is made with the highest quality ingredients, including Ingeo® from Natureworks; a high quality PLA material made from rapidly renewable plant resources in the USA. Combining Polymakers’ innovative R&D technologies, compounding and extrusion systems with Natureworks’ Ingeo® resins yields a reliable 3D printing filament that prints beautiful and accurate patterns.

See “Settings and Specifications” for printing tips and to learn how to achieve the smoothest two-color effect.

Thermal creep is the process of heat spreading unevenly throughout a hotend, a common example is in all metal hotend structures. Once the heat creeps to the cold end, the PLA filament softens prematurely at the cold end and expands, causing a jam. Polymakers’ Jam-Free™ technology increases the heat resistance of the filament itself (not the printed part) up to 100˚C, which prevents the filament from softening prematurely at the cold end and can still melt quickly once it enters the heating zone.

Sample print settings

| Nozzle temperature | 190°C – 230°C |

|---|---|

| Pad temperature | 25°C – 60°C*You may find that lower bed temperatures (e.g. 45°C) work better with PolyTerra™ PLA compared to higher temperatures. |

| Substrate material | Compatible with most common building surfaces. |

| Treatment of the substrate | Use EcoFixy adhesive or apply a thin layer of PVA or PVP adhesive. |

| Cooling fan | ON |

| Print speed | 30 mm/s – 70 mm/s |

| Retraction | Ideal settings for retraction vary from printer to printer. If you find that your retraction settings are causing gaps in your workpiece, the following settings may help. Direct Drive: 0.5 – 1 mm retraction distance at 20 mm/s retraction speed Bowden: 2 – 3 mm retraction distance at 20 – 40 mm/s retraction speed |

| Recommended material for sports | Single extrusion: Self-supportDouble extrusion: PolyDissolve™ S1 (Dissolve in tap water) PolySupport™ (Easily disassembled material for reports) |

Based on a 0.4 mm nozzle. Printing conditions can vary between printers and nozzle diameters.

To produce flatter and more accurately sized parts, PolyTerra™ PLA may work best on your printer at lower bed temperatures (i.e. 45 – 50°C ) compared to higher bed temperatures (i.e. 55 – 60°C+ ) .

Tips for printing dichromatic filaments

1. Dichromatic/two-color filaments print best when all outer perimeters of the part are printed in the same direction for each layer, but not all slitting machines do this by default. You can see the toolpath direction in the slider preview.

2. PolyTerra Dual PLA is carefully wound to ensure proper color alignment on the spool. To achieve the best result, make sure the filament does not twist in the feed path. If the filament twists during printing, the position of the two colors will shift during printing, resulting in a banding effect. Some users find this effect desirable, while others do not. Some level of twisting is common for most 3D printers on the market, but excessive twisting may be more likely on some printers depending on the spool assembly, the hotend, and the extruder design. Using a high quality extruder with dual gearing and direct drive and mounting the spool in a straight position that prevents twisting can help reduce this banding effect.

3. Smaller melt zones are better for dichromatic/two-color filaments. This effect occurs because our 3D printers print with a laminar flow and so the two colors do not mix. Volcano type hot nozzles or CHT type nozzles can cause mixing which reduces the visual effect of the dual color.

4. It may be helpful to print an alignment coin to show you exactly where the color change will occur. The angle will be different for each printer setting, but we have found that if the printer and spool remain in the same orientation, the alignment does not change from spool to spool.

Product Specifications

| Net weight: | 1kg |

|---|---|

| Type of material: | Matte PLA (Fully bio compound) |

| Density: | 1.31 g/cm3 |

| Colour: | Arctic Turquoise/Pastel Banana – Chameleon |

Compatibility

PolyTerra™ PLA has been developed with compatibility in mind to print perfectly on a wide range of 3D printers. The Jam-Free™ technology incorporated into PolyTerra™ PLA can improve compatibility with all hot-end metal structures that suffer from thermal creep.

Of course, with thousands of unique 3D printer models on the market, we can’t guarantee that every type of filament will work with every 3D printer. Experience with cutting machines and adjusting settings is always required to get the most out of a material. Before embarking on an ambitious project, we always recommend printing some known calibration tests to build or make adjustments to the filament profile.

Technical data

All test specimens were printed under the following conditions: Nozzle temperature = 200˚C, build plate temperature = 60˚C, leachate = 100%, cooling fan = on

All specimens were conditioned at room temperature for 24 hours prior to testing.

Thermal properties

| Value | Method of testing |

|

| Glass transition: | 60.6°C | DSC, 10°C/min |

| Heat deflection temperature: | 0.45 MPa – 57.8°C 1.8 MPa – 52°CHDT Curve |

ISO 75 0.45MPa |

| Vicat softening temperature | 62.7°C | ISO 306, GB/T 1633 |

Mechanical properties

| Value | Method of testing |

|

| Jung’s module: (X-Y) |

1882 ± 141 MPa | ISO 527, GB/T 1040 |

| Tensile strength: (X-Y) |

20.9 ± 2.0 MPa | ISO 527, GB/T 1040 |

| Bending force: (X-Y) |

39.6 ± 1.1 MPa | ISO 178, GB/T 9341 |

| Sharpie impact strength: (X-Y) |

5.7 ± 0.4 kJ/m2 | ISO 179, GB/T 9343 |

The typical values presented in the Polymaker data sheet are for reference and comparison only. Due to the nature of 3D printing, they should not be used for design specification or quality control purposes.

Drying and storage

All plastics are hygroscopic, meaning they absorb moisture from the air, which can affect the print quality and strength of printed parts. How quickly this absorption occurs depends on the material and the environment. Polymakers PolyTerra™ PLA fibers are dried and packaged in a vacuum bag with desiccant to ensure the best print quality. When not in use, PolyTerra™ PLA should be stored away from sunlight and sealed in the packaged resealable bag.

Although the strands can be dried, drying will accelerate the aging process of the plastic, making it more brittle over time. Preventing moisture from being absorbed by the filament in the first place is the best solution to keep your filament working to its maximum potential. For long-term storage, we highly recommend storing in a sealed container with a desiccant dryer that reduces relative humidity to 10-20% RH.

If you hear popping sounds and notice that the surface quality of your print is uneven or the color is not consistent, this is a likely indicator that the filament has absorbed too much moisture. PolyTerra™ PLA spools can be dried with a Polymaker PolyDryer™, or other filament dryer using power level 1. Alternatively, if you have a convection oven that is accurate at low temperatures, users can dry the filament in a preheated convection oven at 55˚C for up to 6 hours. Results may vary depending on the accuracy of your oven, so please use caution.

Frequently Asked Questions

Q: Does Jam-Free™ technology prevent any clogging of the nozzle by the filament?

A: Jam-Free™ technology is designed to prevent clogging caused by thermal creep. There are many reasons why a material can clog, such as printing at the wrong extruder temperature or the wrong nozzle height; Polymaker’s Jam-Free™ technology will not prevent clogging in these cases.

Q: Is PolyTerra™️ PLA safe for food?

Answer: PolyTerra™️ Polymaker’s PLA complies with RoHS Directives 2011/65/EU and (EU) 2015/863 and the REACH regulation, meaning it does not contain any toxic or harmful listed substances. However, due to the nature of FDM 3D printing, printed PolyTerra™️ PLA parts may have micro cracks and holes that are invisible to the naked eye, even though the prints appear smooth. Bacteria tend to grow in these micro cracks and holes, and so we do not recommend using 3D printed parts in applications that are in contact with food.

Q: How long does it take to degrade PolyTerra™️ PLA?

Answer: PolyTerra™️ PLA degrades under the specific conditions of industrial composting, namely at a certain temperature and humidity with the presence of micro-organisms. The rate of degradation depends on the size and thickness of the printed part. Polymaker conducted a compostability test, certified to ISO 14855-1, with a third-party laboratory which showed that PolyTerra™️ PLA degraded faster than comparable PLA material. The test was completed by placing small pellets of PolyTerra™️ PLA in 2-4 month old plant compost (incorporating a wide variety of microorganisms) and heating the system to 60˚C. During this process, the PolyTerra™️ PLA will begin to break down into carbon dioxide, water, and mineral salts, and the aforementioned elements are monitored to calculate the mass of PolyTerra™️ PLA degraded. After 45 days, 93.6% of the PolyTerra™️ PLA is degraded, and Polymakers estimates that complete degradation of PolyTerra™️ PLA can take less than 100 days. Polymaker conducted the exact same test with their PolyLite™️ PLA, which is pure ordinary PLA, and after 45 days 79.9% of it degraded. Which means that PolyTerra™️ PLA degrades up to 15% faster than regular PLA.

Q: What auxiliary materials can I use with this product?

A: PolyTerra™ PLA has been developed with excellent deburring properties, allowing users to more easily tear off supports or rafts printed in PolyTerra™ PLA. Polymaker’s PolyDissolve™ S1 or PolySupport™ are the recommended support filaments for PolyTerra™ PLA if your machine can print in multiple materials. If your 3D printer is not equipped to handle multiple materials, self-support can be used.

Q: Do I need to rewind this thread if I want to use it with another spool?

A: We strongly advise you not to manipulate the product by rewinding. All Polymaker filaments are wound with tension but without strain. Rewinding completely rearranges the curvature of the coil and this tension over time can cause most plastics to catastrophically break. If for some reason your printer is blocked from mounting smaller than standard size spools, there may be safe print adapters or external mounting solutions available.

There are no reviews yet.