PLA – CF – Lava gray – Bambu Lab

Product Features

- Carbon fibre texture and minimised ply lines

- Improved mechanical properties

- Stabilized print sizes

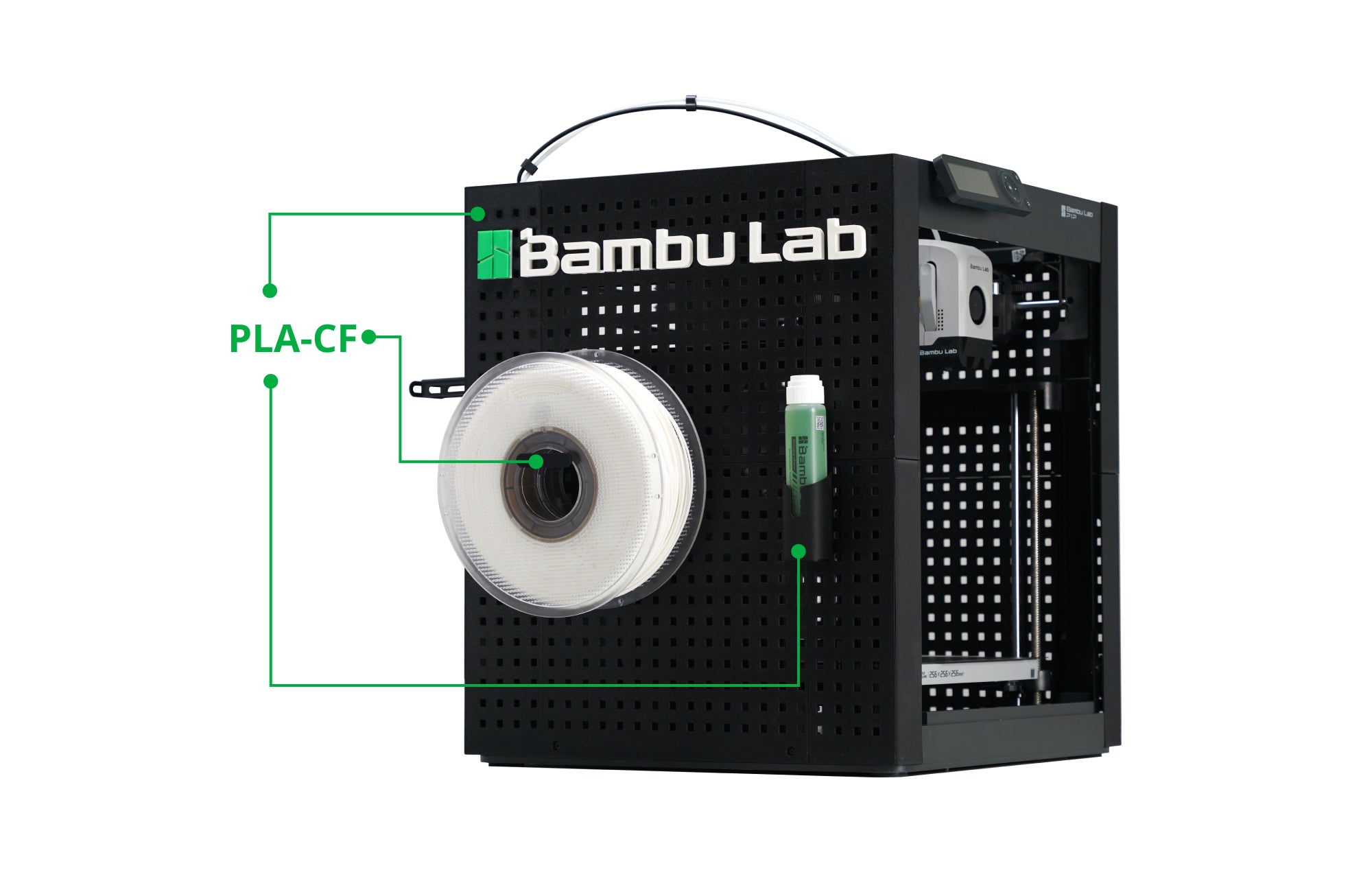

- Comes with reusable main reel

- Diameter: 1.75 mm +/- 0.03 mm

- 1kg

Warnings for use

- 0,2 mm The nozzle is NOT compatible

- NO stainless steel nozzle recommended

- Dry before use for highest print quality

- Compatible with AMS

Bambu PLA-CF

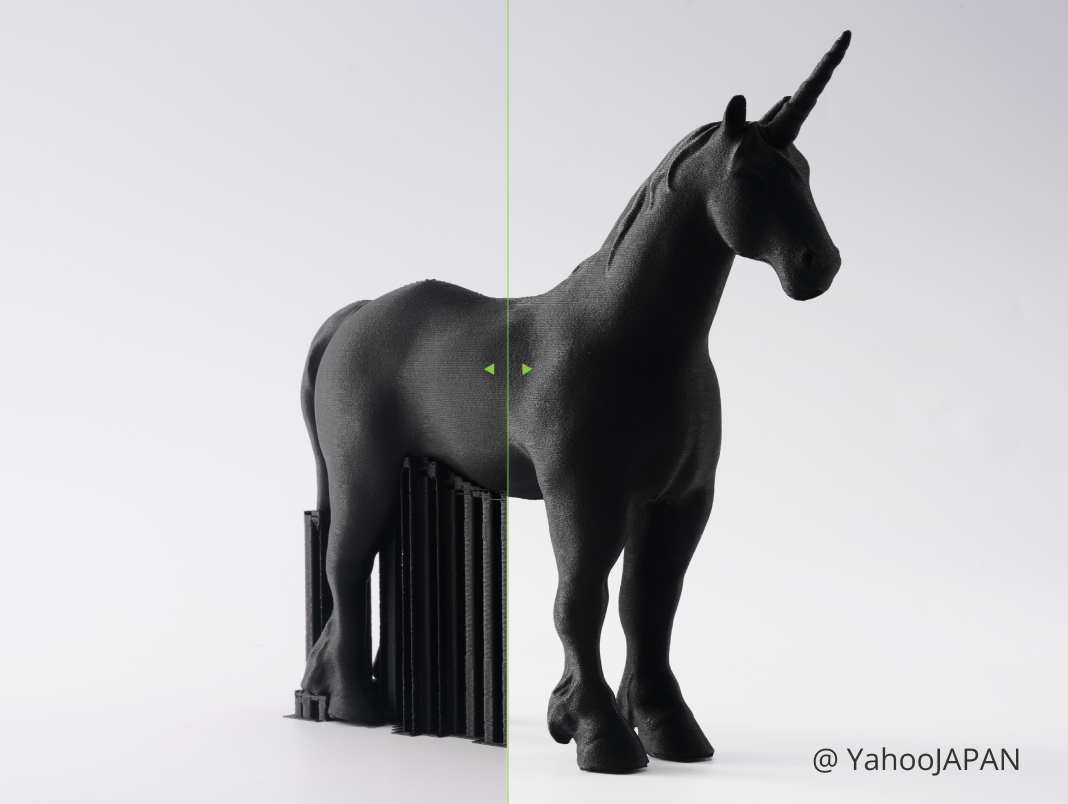

Bambu PLA-CF is carbon fiber reinforced PLA with improved stiffness and strength. PLA-CF is easy to print and beginner friendly like regular PLA. It is AMS compatible with low risk of clogging in high speed printing. Parts get a matte finish with nearly invisible layer lines, making it suitable for printing general engineering parts or models requiring a better appearance, such as bicycle frames, brackets and toys.

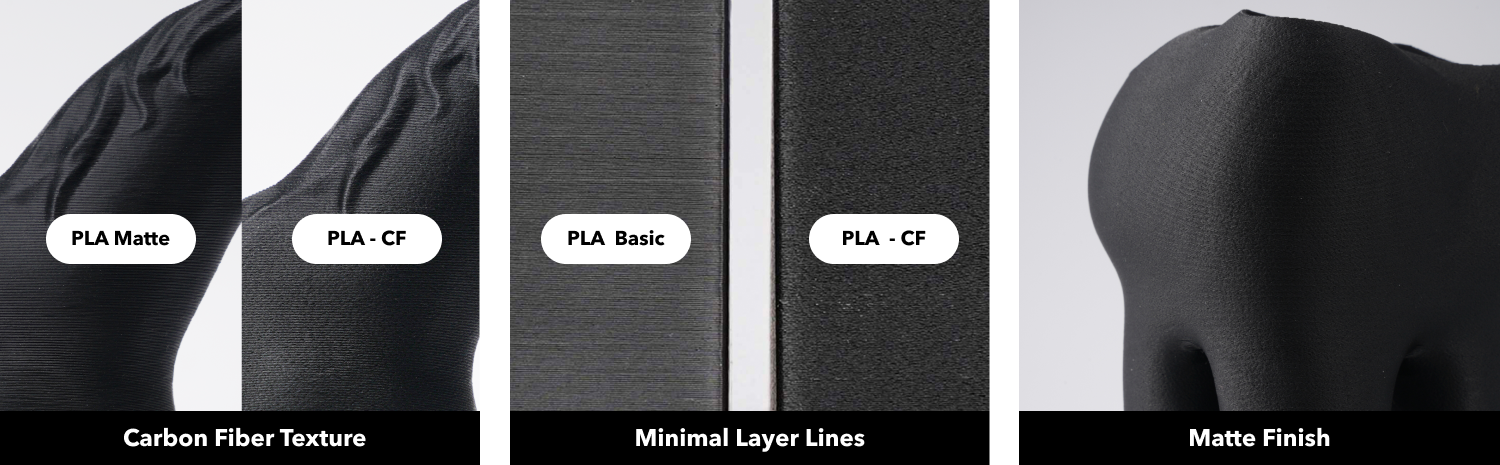

Carbon fibre texture and minimised ply lines

The addition of carbon fiber gives the prints a unique matte finish and effectively hides the ply lines, providing a smooth, premium appearance.

Examples of details

Bambu PLA-CF can be combined with any type of PLA series filament to make your prints more colorful and achieve different texture requirements.

Improved mechanical properties

Bambu PLA-CF outperforms the mechanical properties of PLA Matte in terms of XY flexural strength, Z flexural strength, XY flexural modulus, Z flexural modulus, XY impact strength and Z impact strength by between 20 and 115%, making it more suitable for printing models with higher strength requirements.

Comparison of mechanical properties

| PLA Matte | PLA-CF | Improved % | |

| Tensile strength – XY/MPa | 32 | 38 | 19% |

| Tensile strength – Z/MPa | 25 | 26 | 4% |

| Bending force – XY/MPa | 53 | 89 | 68% |

| Bending force – Z/MPa | 32 | 49 | 53% |

| Bending modulus- XY/MPa | 2360 | 3950 | 67% |

| Bending modulus – Z/MPa | 2040 | 2260 | 10% |

| Impact force – XY/(kJ/m²) | 19.2 | 23.2 | 20% |

| Impact force – Z/(kJ/m²) | 6.6 | 7.8 | 18% |

*Drying of PLA is recommended for humid environment at 55 °C for 8 hours before printing.

Stabilized print size

Bambu PLA-CF is characterized by low shrinkage and resistance to distortion to achieve perfect accuracy of matching between parts of workpieces.

Minimum effort when removing “sports”

The Bambu PLA-CF is designed to maintain itself. It can be removed more easily than regular PLA and maintains a smooth support surface.

Not prone to clogging at high speed printing

Bambu PLA-CF is just as easy to print as regular PLA. It can be printed smoothly and consistently at high speed without clogging.

Compatibility with accessories

| Recommended: | NOT recommended: | |

| Backing: | Cool pad, High temperature or Textured PEI pad | Engineering pad |

| Hotend: | Hardened steel nozzle (0.4/0.6/0.8 mm) | Stainless steel nozzle(0.2 / 0.4 mm) |

| Glue | EcoFixy Glue

Bambu Lab Liquid Glue Glue Stick |

/ |

RFID for smart printing

All print parameters are embedded in the RFID, which can be read via our AMS (Automatic Material System).

Load and print! No more tedious setup steps.

Comparison of parameters

| PETG-CF | PLA-CF | |

| Type of filament: | Carbon fiber filling | Carbon fibre filling |

| Compatibility with Hotenda: | Hardened steel(0.4, 0.6, 0.8 mm) | Hardened steel (0.4, 0.6, 0.8 mm) |

| Pad Compatibility: | Engineering pad, High temperature pad, Textured PEI pad | Cool Plate, High Temperature Pad, Textured PEI Pad |

| Compatibility with AMS : | Yes | Yes |

| Surface: | Shiny | Brushed |

| Print speed: | < 200 mm/s | < 200 mm/s |

| Durability

(impact strength – XY): |

41.2 kJ/m² | 23.2 kJ/m² |

| Strength

(flexural strength – XY): |

70 MPa | 89 MPa |

| Stiffness

(flexural modulus – XY): |

2910 MPa | 3950 MPa |

| Layer adhesion

(impact strength – Z): |

10.7 kJ/m² | 7.8 kJ/m² |

| Heat resistant

(HDT, 0.45 MPa): |

74 °C | 55 °C |

| Recommended infusions for printing | |

| Drying settings (shock drying oven) | 55 °C, 8 h |

| Printing and maintaining the humidity of the container | < 20% RH (Sealed, with Desiccant) |

| Nozzle temperature | 210 – 240 °C |

| Pad temperature (with adhesive) | 35 – 45 °C |

| Print speed | < 200 mm/s |

| Physical properties | |

| Density: | 1.22 g/cm³ |

| Vicat softening temperature: | 69 °C |

| Heat deflection temperature: | 55 °C |

| Melting temperature: | 165 °C |

| Melting index: | 3.7 ± 0.6 g/10 min |

| Mechanical properties | |

| Tensile strength: | 38 ± 4 MPa |

| Fracture extension rate: | 8.4 ± 3.2 % |

| Bending module: | 3950 ± 190 MPa |

| Bending force: | 89 ± 4 MPa |

| Impact Force: | 23.2 ± 3.7 kJ/m² |

Tips before printing

– Drying conditions: 55℃ for 8 hours. After use, store in a dry environment. Dry before use if the material absorbs moisture. For more information, please refer to: Filament drying instructions in WIKI.

There are no reviews yet.