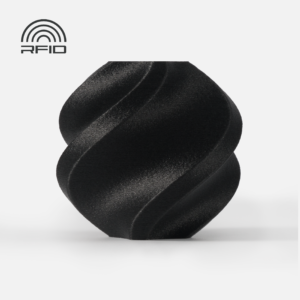

PAHT – CF – with spool – Black – 500 g. – Bambu Lab

Feature

- Low moisture absorption

- Exceptional mechanical properties and layer adhesion

- High tensile strength

- Comes with a high temperature reusable spool

- Diameter: 1.75 mm +/- 0.03 mm

- 500 g.

Warnings for use

- Recommended nozzle 0,6 mm

- Nozzle 0,2 mm is not compatible

- Stainless steel nozzle not recommended

- Dry before use

- Compatible with AMS

- AMS lite NOT compatible

- Closed type printer required

Note: PAHT-CF is an improved version of PA-CF (PA-CF is discontinued).

Bambu PAHT-CF

Bambu PAHT-CF is a composite of PA12 and carbon fibre. Inheriting the advantages of the low water absorption of PA12 and the high performance of carbon fibre, Bambu PAHT-CF offers excellent mechanical and thermal properties that can be retained well even when prints get wet. The higher adhesion of the Z layers and flexibility make it ideal for creating engineering parts such as functional prototypes, machining fixtures, injection molds, jigs and parts for low-volume production.

Low water absorption

50% lower water absorption rate compared to normal PA-CF,

Bambu PAHT-CF retains excellent mechanical properties and dimensional stability even when exposed to high humidity.

Deformation from dry to wet

Comparison of mechanical properties

| Normal PA-CF | PAHT-CF | |

| Saturated water absorption rate/% ( 25 °C, 55% RH ) | 1.70 | 0.88 |

| Flexural strength – XY/MPa (dry) | 128 | 125 |

| Flexural strength – XY/MPa (wet) | 76 | 115 |

| Flexural strength – Z/MPa (dry) | 48 | 61 |

| Flexural strength – Z/MPa (wet) | 34 | 49 |

| Bending modulus – XY/MPa (dry) | 4420 | 4230 |

| Bending modulus – XY/MPa (wet) | 2210 | 3640 |

| Bending modulus – Z/MPa (dry) | 1470 | 1820 |

| Bending modulus – Z/MPa (wet) | 770 | 1480 |

| Rate of decrease in mechanical properties after water absorption/% | 40%-45% | 12%-18% |

*Both PA-CF and PAHT-CF must be dried at 80 °C for 12 hours before printing.

Exclusive Z-bonding

Bambu PAHT-CF exhibits much higher adhesion in the Z-layers compared to normal PA-CF, enabling it to withstand high levels of impact or stress without breaking or deforming.

Implementation of Z-layer

| Normal PA-CF | PAHT-CF | Enhanced

% |

|

| Flexural strength – Z/MPa | 48 | 61 | 27% |

| Flexural strength – Z/MPa | 1470 | 1820 | 24% |

| Impact resistance – Z/(kJ/m²) | 5.7 | 13.3 | 133% |

*Both PA-CF and PAHT-CF must be dried at 80 °C for 12 hours before printing.

High tensile strength

Bambu PAHT-CF is designed to meet the requirements of a variety of industrial and engineering applications where high strength and durability are required.

Designed to withstand high temperatures

The heat distortion temperature of Bambu PAHT-CF is up to 194℃ (0.45 MPa)*, making it useful in applications where printed parts can be exposed to high temperatures without warping or losing their strength.

* Long-term temperature stability is related to the structure and usage scenario of the model itself.

Reusable reel

Reusable reel

Bambu PAHT-CF comes with a high temperature resistant reel that does not deform in the drying process. Continuing our concept of reducing plastic waste, the spool can also be reused with other Bambu refills.

Compatibility of accessories

| Recommended | Not recommended | |

| Backing: | Smooth PEI backing , Textured PEI backing | Cool SuperTack pad |

| Hotend: | Hotend with hardened steel nozzle 0.4mm / 0.6mm (recommended) / 0.8mm* | Hotend with stainless steel nozzle all sizes |

| Glue: | Glue stick / EcoFixy glue | Liquid glue |

* As nozzle size increases, the likelihood of clogging decreases, but print quality also decreases. It is therefore recommended to use a 0.6 mm hardened steel nozzle to avoid clogging while maintaining optimum print quality.

RFID for smart printing

All print parameters are embedded in the RFID, which can be read via our AMS (Automatic Material System).

Load and print! No more tedious setup steps.

Comparison of parameters

Learn more about the comparison of different threads in the Bambu Thread Guide >>

| PET-CF | PAHT-CF | |

| Composition: | PET, carbon fiber | PA 12 and other long-chain PA, carbon fibre |

| Host Compatibility: | 0.4mm / 0.6mm (recommended) / 0.8mm hardened steel hotend | |

| Compatibility of the build plate: | Cool SuperTack pad, SmoothPEI pad, Textured PEI pad | Smooth PEI pad, Textured PEI pad |

| Glue: | Glue stick / Liquid glue / EcoFixy glue | Glue Stick / EcoFixy Glue |

| AMS Compatibility: | NO | YES |

| Print speed: | < 100 mm/s | < 100 mm/s |

| Durability (impact strength – XY): | 36.0 kJ/m² | 57.5 kJ/m² |

| Strength (flexural strength – XY): | 131 MPa | 125 MPa |

| Stiffness (flexural modulus – XY): | 5320 MPa | 4230 MPa |

| Layer adhesion (impact strength – Z): | 4.5 kJ/m² | 13.3 kJ/m² |

| Heat resistant(HDT, 0.45 MPa): | 205 °C | 194 °C |

| Absorption rate of saturated water / % (25 °C,55% RH): | 0.37 | 0.88 |

| Recommended print settings | |

| Drying settings (shock drying oven): | 80 °C, 8 – 12 h |

| Printing and maintaining the humidity of the container: | < 20% RH (Sealed, with desiccant) |

| Nozzle temperature: | 260 – 290 °C |

| Bed temperature (with adhesive) : | 80 – 100 °C |

| Print speed: | < 100 mm/s |

| Physical properties | |

| Density: | 1.06 g/cm³ |

| Vicat softening temperature: | 220 °C |

| Heat deflection temperature: | 194 °C |

| Melting temperature: | 225 °C |

| Melting index: | 14.4 ± 2.0 g/10 min. |

| Mechanical properties | |

| Tensile Strength | 92 ± 7 MPa |

| Breaking Elongation Rate | 8.4 ± 1.8 % |

| Bending Modulus | 4230 ± 210 MPa |

| Bending Strength | 125 ± 7 MPa |

| Impact Strength | 57.5 ± 3.4 kJ/m² |

Printing tips

– Drying conditions: 80℃ for 8 hours. PAHT-CF is highly sensitive to humidity. To achieve optimum print performance, additional drying before use and after storage is recommended. For more details, please refer to: Filament Drying Instructions in WIKI.

– Bambu PAHT-CF has high thermal insulation requirements during the printing process, making it unsuitable for use with open frame printers.

– For better printing results, please see: Tips for printing engineering materials in WIKI.

– When printing a pattern with support, we recommend removing the support structures within 2 hours of printing to prevent them from sticking after absorbing moisture. If sticking occurs, dry the model to facilitate removal.

Test conditions

| Specimen Size: | 150mm(L)*10mm(W)*2.5mm(H) |

| Loading weight: | 1.02 kg |

| Print settings: | All samples were printed at 280℃ nozzle temperature, 100℃ bed temperature and 100mm/s printing speed. |

| Filament states: | -Dry specimens were annealed and dried at 80℃ for 12 hours prior to testing.

-Wet specimens were placed under ambient conditions of 25℃, 55% relative humidity and reached the saturated water absorption rate. |

What’s in the box?

There are no reviews yet.