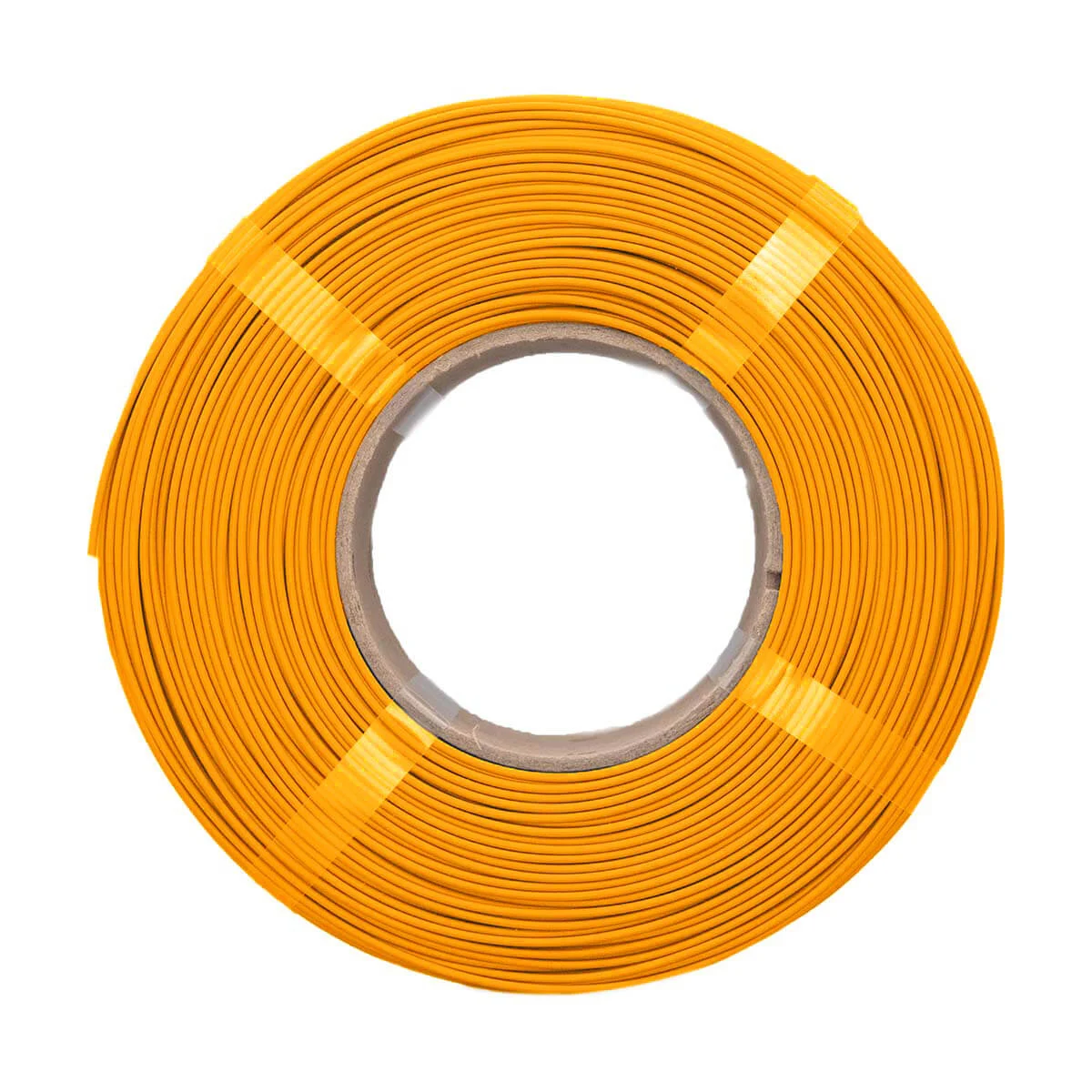

PETG Refill – Orange – Azurefilm

Refill PETG

PETG Refill films have the same properties as our PETG Original films. In addition to being an environmentally friendly solution, these filaments are tough, durable and can withstand temperatures up to 80°C. Our Refill PETG filaments are very easy to handle and are ideal for beginners.

What is new?

- We removed the plastic ties and replaced them with a better option to make unpacking easier.

- The filament tail is now completely straight. This prevents it from getting stuck in the spool and ruining your print when the filament runs out.

- Perfect compatibility with AzureFilm and Bambu Lab spools.

Print Recommendations:

- For best results, print at 220-240°C.

- The recommended printing table temperature is 80°C.

- Use a glass bed, PEI sheet, Kapton or blue tape for the build platform with 3Dlac spray or EcoFixy adhesive.

*Ideal temperature may vary when using different printers.

Our PETG Refill Filaments are fully compatible with the AzureFilm base spool – the only spool you’ll ever need. By using this reusable spool, you can join us in reducing waste and minimizing environmental impact.

The AzureFilm Master Spool is our reusable spool that provides a sustainable and cost-effective 3D printing solution. The spool is a set of two reusable discs made using the injection molding method. This ensures the high durability and precision of the spool.

By purchasing and reusing our Master Spool, you are contributing to a cleaner environment while enjoying a reliable and easy-to-use product compatible with most 3D printers.

Characteristics and properties

| Functions | Value |

|---|---|

| Flexibility: | Medium |

| Strength: | High |

| Durability: | High |

| Difficult to use: | Low |

| Shrinkage/Distortion: | Minimum |

| Soluble: | NO |

| Diameter: | 1.75mm |

| Manufacturer: | AzureFilm |

PETG, one of the strongest and most durable 3D printing filaments, stands for Polyethylene Terephthalate Glycol. PETG filaments feature the printability of PLA and the strength of ABS. This type of filament is best suited for printing functional parts of a 3D model because of the material’s strength and its superior rubber impact resistance characteristic.

If you want to create high-quality 3D prints like the pros with PETG filament, you need to know all about this filament.

What is PETG filament?

As mentioned, PETG retains 2 excellent properties of PLA and ABS. This is why PETG filaments are so strong and durable. Printing with PETG filaments is relatively easy, and best of all, you don’t even need a heated bed.

PETG filaments are suitable for both beginners and experienced users. They love this filament for its versatility and wide range of applications. Not to mention the bright colours of PETG filaments.

So finding the right shade of filament is not something you need to worry about. PETG filaments are also available in different varieties such as clear, glossy and metallic filled. If you want to print premium 3D models and have fun with them at the same time, choose PETG filaments.

Due to their chemical resistant and thermoformable properties, PETG filaments are extensively used in the food industry for the production of drinking bottles and cooking oil containers. PETG filaments are also widely used to manufacture FDA-approved food storage containers.

The cosmetics industry also prefers PETG filaments over others for packaging their products. The filaments are very light but strong, which reduces distribution costs. And lower costs mean more revenue, so it’s not hard to explain why these industries choose PETG filaments.

How are PETG filaments produced?

To fix the problems with glycol-based synthetic fibers and phthalic acid polymers, scientists came up with a solution to fuse the two substances and create something strong. Thus, in 1941, PET, or polyethylene terephthalate, came into being. The scientists behind PET were James Dixon and John Winfield.

They use the esterification process to create long-chain PET molecules. This process involves heating terephthalic acid and glycols. With this process, they convert PET into fibres. These fibers have low solubility but higher melting temperatures.

At this point, PET became really popular as people started using it in industries such as food packaging, textiles, rigid bottle manufacturing, etc. Even after all this PET still has a few problems. One of the most serious problems of PET is its tendency to crystallize. At high temperatures, the filaments crystallize and become opaque, which deforms the structure of the product.

To eliminate this problem, scientists started using cyclohexane dimethanol instead of ethylene glycol. This helped eliminate the crystallization problem and improved heat resistance. Thanks to these modifications, we can now use PETG filaments for 3D printing, thermoforming and other various applications where higher temperature is a crucial aspect.

PETG filaments vs PLA filaments: what are the differences?

Both PLA and PETG are very popular among consumers. In fact, in a report published in 2018, 6% of consumers worldwide use PETG to print their 3D models. People often ask which fiber is better, PLA or PETG? To come to this conclusion, you need to understand the difference between the filaments. And those differences include:

| PETG | PLA |

|---|---|

| Compared to PLA, PETG is stronger, which reduces the likelihood of deformation or distortion of the seal. PETG is ideal for advanced users. | PLA is a filament that most beginners choose because of the ease of printing. Filament is softer and easier to print. |

| PETG filaments are better suited for glossy, bright, durable and strong prints. | The PLA filaments produce brilliant high-quality 3D prints. |

| PETG uses polyethylene terephthalate as the raw material for the filaments. | The raw material for PLA is sugar cane and corn starch. No harmful fumes are emitted in the production of this filament. |

| It is not biodegradable like PLA, but you can easily recycle it. | PLA is an environmentally friendly filament as it is biodegradable. |

| The durability of PETG is quite high. Its tensile strength ranges from 4100 to 8500 psi. | PLA fibres have poor impact resistance and their durability is also lower compared to PETG. Its tensile strength is up to 7250 psi, which is less than PETG. |

| PETG is more flexible and impact resistant than PLA. | It’s not that PLA isn’t flexible. But compared to PETG it is less flexible. |

| The melting point of PETG is 260°C, making it a filament with high heat resistance. Thanks to this property, you can keep your printed parts in the sun. | PLA is not the filament to use for 3D printing models with external applications, as its melting temperature ranges from 160°C to 180°C. So sun exposure will deform your prints. |

PLA and PETG fibers are great for 3D printing models. Both filaments have their pros and cons. So instead of asking which is the best filament, you should ask yourself which would be best for your project. If you want your prints to be strong and durable, PETG would be the best. But if you don’t have much experience and want a filament that is easy to print with, PLA should be your filament of choice.

So before you choose, consider the above facts and compare them with your needs. See which filament works best for you.

How to print with PETG filaments

When printing with PETG, there are some important factors to keep in mind to ensure robust and high-quality 3D prints every time. These factors include:

Printing temperature

Typically, the best temperature for printing PETG filaments is in the 220-240° Celsius range. When complying with this temperature, the bonding of the layers of the different parts turns out great. In addition, the printing surface remains smooth.

Bed temperature

The temperature of the print bed must not exceed 80° and 100° Celsius. Maintaining this temperature is important as it reduces the likelihood of print distortion. This also helps ensure that the first layer of PETG adheres firmly to the bed. This minimizes layer spillage and keeps the print area nice and warm. The corners of large printed parts do not peel off as often if the print bed is heated properly.

Gluing the bed

The best print bed for PETG filament includes PEI, Kapton tape, blue tape, and glass beds. PETG attaches easily to PEI sheets. Removal is also easy when the print has cooled. If you are printing on a large print area, use PEI sheets.

Glass beds are also great in terms of seal bonding and removal. These beds are sturdy enough to take the shock of the nozzle, and are less susceptible to human error. Blue strips are also great. With these, you don’t need to buy a new print bed. Just cover your print bed with the tape and it will do the job.

Print speed

The ideal printing speed for PETG filaments should be above 50 mm/s. Keep it around 60-80 mm/s for better PETG prints. Higher than this value may cause filament formation or the corners of the print to peel off. PETG filaments may stretch when printing at speeds below 50 mm/s. This can also lead to spotting.

Advanced tips and troubleshooting for PETG filaments

You may encounter some common problems when printing with PETG filaments. But don’t worry, just follow our troubleshooting tips to maintain the quality of your prints.

Stringing

Stubs are produced when the temperature of the extruded material becomes too high. The excessive heat liquefies the PETG more than necessary, so the filament eventually creates strands. Too low draw settings and nozzle size are other causes of PETG filament formation.

To avoid this problem, readjust the restriction settings and lower the nozzle temperature. Use the correct nozzle type. Reducing the print speed can also help in this regard.

Deformation

This problem occurs when the ambient humidity is low or the nozzle temperature is too high. Overhangs left unsupported can also cause deformation. The best thing you can do to reduce is the problem is to make the necessary adjustments.

Gluing the bed

This problem can occur if the filament is wet, the printing surface is not suitable, the temperature is too low, or the print speed needs adjustment. You can troubleshoot this problem by checking that the nozzle and print bed temperatures range from 220°C to 260°C and 80° and 100° Celsius, respectively. Drying the PETG filaments and re-adjusting the speed also helps.

Plugging of the nozzle

Give the hot end enough time to cool and you won’t have to face the problem of nozzle clogging. Lack of ventilation and low ambient humidity also cause this problem. So arrange better ventilation and readjust the ambient humidity and heat of the print.

Absorption of moisture

PETG fibres also absorb moisture from the air or water. Excessive moisture lowers filament quality as well as printer functionality. You can dry the PETG in the oven to remove moisture, or use a filament dryer.

PETG filament recharging

AzureFilm is proud to have a range of PETG refill filaments. These fillers are extremely strong, durable, food safe and odourless. You have 6 color options available: White, tiger orange, black, blue, red lipstick and gray.

The fillers are manufactured by fusion of strength and flexibility, therefore their shrinkage is minimal. You can 3D print large models or produce mechanical parts in robotics with our Refill PETG filament.

To keep the environment clean and reduce waste, try our REELfinity spool. Loadable PETG filaments weighing 1 kg are designed to be used with the spool. So what are you waiting for? Buy our PETG filament refills today along with our REELfinity spool.

Frequently asked questions about PETG filaments

What are the tips for using PETG filaments?

Nozzle temperature, print speed and incorrect retraction settings usually cause many problems when printing with PETG. So watch out for these factors and make appropriate adjustments when necessary.

What are PETG filaments best used for?

PETG filaments are widely used in the production of food containers, bottles and packaging for cosmetic and medical devices.

What are the common problems with PETG?

Fraying, warping, staining and poor bed fit are some of the most common problems with this thread.

Why is it so difficult to print with PETG?

Printing with PETG filaments is relatively more difficult as a certain level of experience is required. In addition, the post-processing stage can be a bit tricky for many people. But when you get familiar with the filament, working with it becomes easier.

PETG filaments are great for printing. But to enjoy the printing process, you actually need to know the best practices for PETG filaments. Hopefully, this guide will help you understand everything you need to know about PETG to get a better printing experience.

There are no reviews yet.