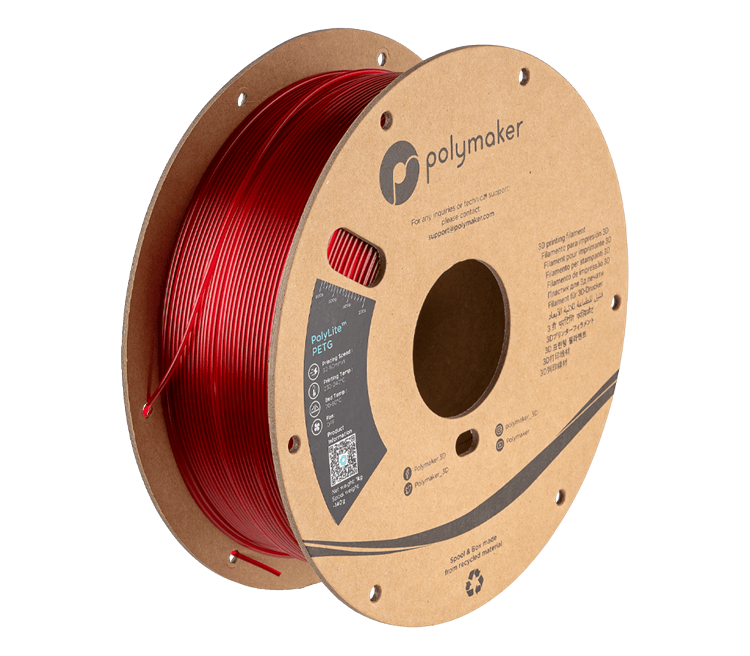

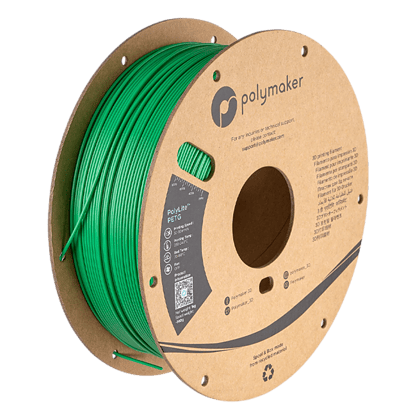

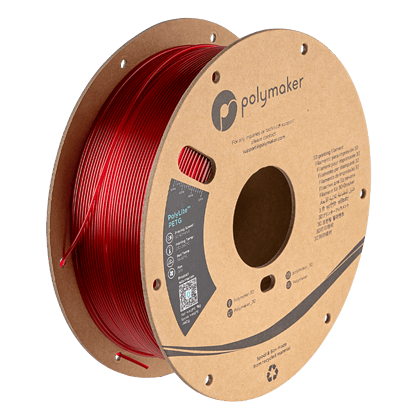

PolyLite PETG – transparent red – translucent red – Polymaker

Product Features

- High quality and heat resistant PolyLite™ PETG

- High Quality PETG Polymaker.

- Good mechanical strength and durability.

- High heat resistance up to 78℃ HDT.

- Less deformation compared to other high temperature materials (ABS, ASA, PC).

- Cardboard spool and packaging (made of 100% recycled cardboard)

- Consistent color and tolerance (1.75 mm diameter +/- 0.03 mm)

PolyLite™ is a family of 3D printing filaments manufactured from the finest raw materials to deliver exceptional quality and reliability. PolyLite™ covers the most popular 3D printing materials to meet your everyday design and prototyping needs. PolyLite™ PETG is an affordable PETG filament with balanced mechanical properties and affordable printer compatibility.

Functions

- Balanced mechanical properties – PolyLite™ PETG features well-balanced mechanical properties; it offers good strength while outperforming regular PLA in durability.

- Heat resistance – PolyLite™ PETG features heat resistance up to 80°C combined with good durability, enabling PolyLite™ PETG to be used for more functional applications where PLA will not have the durability or heat resistance, such as lighting fixtures, vibrating parts or more functional product design prototypes.

- Easy sanding – PolyLite™ PETG is easier to post-process than regular PLA, allowing it to be sanded to a nice smooth finish.

- Excellent compatibility – PolyLite™ PETG filament is compatible with a wide range of 3D printers; PETG shares many advantages of PLA, such as fantastic dimensional stability with minimal distortion compared to other high temperature materials. A heated bed with a temperature of 80°C is required.

- Uncompromising Quality – With Polymaker’s industry-leading quality control process and rigorous in-house testing, you can be confident that PolyLite™ PETG will produce beautiful, reliable and accurate printed parts.

Comparison of materials

Compare PolyLite™ PLA, PETG, ABS, ASA and PC.

Please note that other product ranges such as PolyMax™ PLA, PETG and PC have different properties compared to the PolyLite™ range.

| PolyLite™ PLA | PolyLite™ PETG | PolyLite™ ABS | PolyLite™ ASA | PolyLite™ PC | |

| Material: | PLA | PETG | ABS | ASA | PC |

| Description: | High hardness PLA | High quality PETG | Durable ABS | UV & weather resistance ASA | Robust PC |

| Nozzle temperature range: | 190°C – 230°C | 230°C – 240°C | 245°C – 265°C | 240°C – 260°C | 250°C – 270°C |

| Pad Temperature: | 25 – 60°C | 70 – 80°C | 90 – 100°C | 75 – 95°C | 90 – 105°C |

| Incloser: | Useful when making large parts | Recommended for making large parts | Recommended | Recommended | Highly recommended |

| Heated chamber: | N/A | N/A | Recommended for making large parts | Recommended for making large parts | Recommended for making large parts |

| Hardness (X-Y): |

High | Moderate | Moderate | Moderate | High |

| Tensile strength: (X-Y) |

46.6 MPa | 31.9 MPa | 33.3 MPa | 43.8 MPa | 62.7 MPa |

| Endurance (X-Y): |

Low impact strength | Moderate impact force | High impact strength | High impact strength | Low impact strength |

| Glass transition temperature: | 61°C | 81°C | 101.1°C | 97.8°C | 113.4°C |

| Heat deflection temperature (0.45 MPa): | 59.8°C | 78.4°C | 99.6°C | 102.6°C | 111.2°C |

| Special feature: | – High hardness and strength. – Easy to print, widest printer compatibility, best dimensional stability and lowest temperature requirements. |

– It combines good printability, mechanical properties and heat resistance with better dimensional stability compared to ABS, ASA and PC. | – Balanced mechanical properties, durability and high heat resistance. – Easy to sand, paint and glue. |

– Resistant to UV rays, rain and environmental cracking. – Balanced mechanical properties, durability and high heat resistance. – Easy to sand, paint and glue. |

– High hardness, strength and heat resistance. – Transparent filament for applications that require good light scattering. |

| Popular with : | Total use | Design and functional prototyping | Design, functional prototyping and manufacturing | Functional prototyping, manufacturing, mining, automotive | Production, lighting, fixtures |

Print settings

| Nozzle temperature: | 230°C – 240°C |

|---|---|

| Pad Temperature: | 70°C – 80°C |

| Surface material for construction: | Works well with most substrates, e.g. glass, BuildTak®, etc. Rigid build pads are recommended over magnetic flexible pads. |

| Surface treatment of the building: | Apply Magigoo Original or PVA or EcoFixy adhesive to the building surface to improve bonding. |

| Incloser: | Not required, but helpful to keep out drafts and maintain a stable printing environment.

If closed, on some printers it is recommended that the door or lid be open to prevent the environment from getting too hot. |

| Cooling fan: | LOW for better surface quality OFF for better strength |

| Print speed: | 30 mm/s – 50 mm/s |

| Retraction: | Ideal retraction settings vary from printer to printer and depend on the hot end. The following settings are a good starting point for many machines. Direct drive: 1 mm retraction distance at 20 mm/s retraction speed Bowden: 3 mm retraction distance at 40 mm/s retraction speed |

| Recommended material for sports: | Single extrusion: Self-supporting.Double extrusion: PolyDissolve™ S1 (PVA) can sometimes support some models depending on their geometry. |

The above printing recommendations are based on a 0.4 mm nozzle. Please note that ideal printing conditions may vary depending on your 3D printer settings. For high-speed 3D printers, be sure to increase the extrusion temperature to use higher print speeds.

PETG is a “patch” material compared to regular PLA. When it comes to printing with PETG without filaments or droplets, it is recommended to keep the filament dry and adjust temperatures, retraction, speeds and flow to avoid excess material build-up on the nozzle.

Product Specifications

| Weight: | 1kg |

|---|---|

| Type of material: | PETG |

| Density: | 1.25 (g/cm3 at 21.5˚C) |

| Colour: | Translucent Red |

Compatibility

PolyLite™ PETG has been developed with compatibility in mind to print perfectly on a wide range of 3D printers equipped with a heated bed. PolyLite™ PETG, like other materials, is hygroscopic. This means that it is susceptible to absorbing moisture from the atmosphere, which can subsequently affect the quality and mechanical properties of the final prints. See “Storage and Drying” details below for instructions on protecting PolyLite™ PETG.

Of course, with thousands of unique 3D printer models on the market, we can’t guarantee that every filament type will work with every 3D printer.

Technical data

All test specimens were printed under the following conditions: nozzle temperature = 240˚C, build plate temperature = 80˚C, leachate = 100%, cooling fan = OFF

All specimens were conditioned at room temperature for 24 hours prior to testing.

THERMAL PROPERTIES

| Values: | Test method: |

|

| Glass transition: | 81°C | DSC, 10°C/min |

| Heat deflection temperature: | 0.45MPa – 78.4°C 1.8 MPa – 74.8°CHDTCurve |

ISO 75 |

| Vicat softening temperature: | 84°C | ISO 306, GB/T 1633 |

MECHANICAL PROPERTIES

| Values: | Test method: |

|

| Jung’s Module (X-Y): |

2,116.8 MPa | ISO 527, GB/T 1040 |

| Tensile Strength (X-Y): |

50.8 MPa | ISO 527, GB/T 1040 |

| Tensile strength:(Z) | 42.8 MPa | ISO 527, GB/T 1040 |

| Elongation at break:(X-Y) | 8.4% | ISO 527, GB/T 1040 |

| Bending modulus (X-Y) | 1,898.5 MPa | ISO 178, GB/T 9341 |

| Bending force (X-Y): |

69.6 ± 0.8 MPa | ISO 178, GB/T 9341 |

| Sharpie impact strength (X-Y) |

2.6 ± 0.2 kJ/m2 | ISO 179, GB/T 1043 |

The typical values presented in the Polymaker data sheet are for reference and comparison only. Due to the nature of 3D printing, they should not be used for design specification or quality control purposes.

STORAGE AND DRYING

- Before packaging, PolyLite™ PETG is dried to ensure the best print quality and the filaments are vacuum sealed to protect them from moisture. When not in use, PolyLite™ PETG should be stored away from sunlight in the packaged resealable bag.

- Like other PETG filaments, PolyLite™ PETG is susceptible to absorbing moisture from the air, which can subsequently affect the quality and mechanical properties of the final prints. We recommend that PolyLite™ PETG be stored in a PolyBox™ or dry cabinet during printing to prevent moisture absorption that will reduce print quality. PolyBox™ stores the filament under dry conditions (relative humidity 15% or less).

- If you hear popping sounds and notice that the surface quality of your print is uneven or the color is not consistent, this is a likely indicator that the filament has absorbed too much moisture. PolyLite™ PETG spools can be dried in a preheated convection oven at 65˚C for up to 6 hours. Results may vary depending on the accuracy of your oven, so please use caution.

FREQUENTLY ASKED QUESTIONS

Q: Does PETG print just like PLA?

A: Most types of filaments are compared to PLA or ABS when discussing how they are printed. PETG does not print exactly like PLA, but has more similar printing characteristics to PLA than ABS, especially when discussing deformation. Ultimately, how easy a material is to print depends on the hardware and previous user experience. We typically find PETG to be a fickle material when it comes to adjusting surface quality settings, but most users find the transition from PLA to PETG to be easier than the transition from PLA to ABS when it comes to printing large parts. The main differences between PLA and PETG are that the heated bed is very important when printing PETG, the optimum printing temperatures are different and the housings can be more useful when printing certain geometries.

Q: Can PETG be printed on large scales without warping?

A: In terms of dimensional stability, PETG is easier to print than high temperature materials such as ABS. When using a desktop 3D printer, very large parts that would warp or crack with ABS can often be printed from PETG without these issues. Typically PETG can be printed at large scales without the need for a casing, but this can vary depending on the adhesion of the first layer, the heating, and the heated bed. For 3D printers that do not uniformly heat the entire bed surface, an enclosure can be very useful. Enclosures can also help prevent drafts.

Q: Can PETG replace ABS?

A: Many users point to PETG as an excellent substitute for ABS, which is certainly true for some applications. When comparing plain PETG and plain ABS; ABS is still the stiffer and more heat resistant filament, but many end users find that PETG is easier to print without warping. If users are not going to take advantage of the extra performance offered by ABS, the improved printability of PETG may make PolyLite™ PETG a suitable candidate.

Q: Do I need to rewind this thread if I want to use it with another spool?

A: We strongly recommend not to tamper with the product by rewinding. All Polymaker filaments are wound with tension, but without strain. Rewinding completely rearranges the curvature of the coil and this tension over time can cause most plastics to catastrophically break. If for some reason your printer is blocked from mounting smaller than standard size spools, there may be safe print adapters or external mounting solutions available.

Don’t know where to start? Or which thread would be right for your application? Contact us today!

Polymaker is an international team that is passionate about 3D printing. They produce the finest 3D printing materials, controlling every stage of production. With a diverse portfolio of materials ranging from high-performance plastics to unique aesthetic solutions, Polymaker will continue to add cutting-edge materials to their ever-growing portfolio.

At the heart of Polymaker is their research and development lab, where all Polymaker materials are formulated and refined from scratch to create best-in-class 3D printing materials. Their precision testing equipment combines the latest advances in technology to ensure they are ahead of the game.

PolyLite™ PETG, like all other Polymaker materials, is manufactured using state-of-the-art polymer processing technology and equipment. Polymaker’s stringent quality control processes ensure industry standards of reliability for consistent customer service.

Tolerance – Polymakers’ custom-developed extrusion, control and monitoring solutions ensure that filament tolerance and roundness meet Polymakers’ stringent quality standards.

Reliable mechanical, coloring and printing properties – Each batch of filament products is tested to ensure that all quality specifications (melt flow, softening point, mechanical, diameter, roundness) are met.

Drying and Vacuum Sealing – All Polymaker filaments are dried to a moisture level before being packaged < 0.1% to ensure the best print quality, and are vacuum sealed to protect the filaments from moisture. All vacuum packed products are allowed to sit for 24 hours before being boxed to ensure they do not leak.

PolyLite™ PETG is wound on 1 kg Polymakers cardboard spools made from recycled cardboard. The cutout and weight gauge on the side of the spool make it easy to see exactly how much filament is left for your next printing project. PolyLite™ PETG’s recycled cardboard packaging and cardboard spool are the first step taken towards creating more environmentally sustainable products. The spool is packaged in a vacuum-sealable bag to ensure your filament doesn’t get wet. Like all other PETG filaments, PolyLite™ PETG is hygroscopic, so we recommend that you keep this pouch for storing your filaments.

There are no reviews yet.