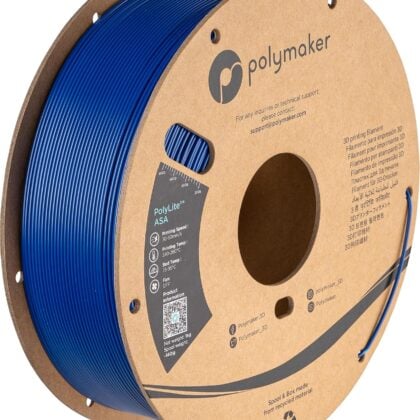

PolyLite ASA – blue – blue – Polymaker

PolyLite ASA – blue – blue – Polymaker is a UV resistant filament with a galaxy effect in the night sky.

High Quality Polymaker ASA.

An eye-catching galactic effect achieved with reflective glitter particles.

Exceptional UV and weather resistance.

Great mechanical strength and durability.

High heat resistance up to 102℃ HDT.

Attractive matt/satin surface finish.

Cardboard reel and packaging (made of 100% recycled cardboard)

Consistent color and tolerance (1.75 mm diameter +/- 0.03 mm)

PolyLite™ is a family of 3D printing filaments manufactured from the finest raw materials to deliver exceptional quality and reliability. PolyLite™ covers the most popular 3D printing materials to meet your everyday design and prototyping needs. PolyLite™ Galaxy ASA is a high quality ASA with a hint of reflective sheen inside to create a series of sparkling galaxy colours. PolyLite™ Galaxy ASA is an alternative to ABS with improved weather resistance. Its UV resistance and excellent mechanical properties make it an ideal choice for real-life applications.

Features

- Galaxy Star Effect – PolyLite™ Galaxy ASA is a high quality, UV resistant ASA with a hint of reflective glitter inside that creates a series of sparkling colours with an eye-catching galaxy effect. This starburst effect makes PolyLite™ Galaxy ASA a great option for applications requiring a standout yet functional material.

- UV Resistant – With excellent weather resistance (UV, water and heat) PolyLite™ Galaxy ASA is the ideal choice for printing parts that need to survive harsh outdoor conditions. Most plastics tend to become brittle and their color yellow when exposed to UV radiation or sunlight, but with PolyLite™ Galaxy ASA the appearance and mechanical properties of your 3D prints are not negatively affected by UV light.

- Waterproof – PolyLite™ Galaxy ASA is resistant to environmental stress cracking (ESC). This allows printed parts to stand up to outdoor, high humidity and rain for long periods of time.

- Alternative to ABS – PolyLite™ Galaxy ASA performs better in both thermal and mechanical properties compared to common ABS filaments. It also features a Vicat softening temperature of 105°C, which slightly exceeds that of ABS.

- Excellent print quality – PolyLite™ Galaxy ASA prints parts with a beautiful matte surface finish suitable for printing production parts. Made from only the highest quality materials, PolyLite™ Galaxy ASA provides excellent print quality and reliability.

- Uncompromising Quality – With Polymaker’s industry-leading quality control process and rigorous in-house testing, you can be confident that PolyLite™ Galaxy ASA will produce beautiful, reliable and accurate printed parts.

Applications

PolyLite™ ASA has quickly become a popular and cost-effective engineering material for applications requiring high heat resistance, weather resistance or a good balance between strength, durability and stiffness. Weather resistance can be divided into 3 factors: UV resistance, water resistance and thermal stability, of which ASA outperforms many other plastics. Compared to other materials, PolyLite™ ASA is resistant to environmental cracking, allowing printed parts to stand up to outdoor, high humidity and rain for long periods of time.

PolyLite™ ASA is sometimes used for decorative patterns, but is often chosen for technical projects such as:

- Functional prototypes.

- Plastic parts for 3D printers and enhancements.

- Spare and replacement plastic parts.

- Custom and non-standard automotive parts.

- Production of end-use products.

- Plant pots, household items and outdoor furniture.

- Writing logos and character texts.

- Staples and production aids.

- Cases and housings for outdoor use.

- Assemblies that require gluing or painting.

- Anemometers and research equipment.

Like ABS and other high-temperature plastics, ASA can be printed without a casing, but the patterns will print with more stress and a greater chance of distortion as part size increases. For most applications, it is recommended to print with a housing, and for large or dense print projects, a printer with a controlled heating chamber will be required.

Research and development for PolyLite ASA began when Polymaker developed and produced the 3D printing material for the world’s largest 3D printing pedestrian bridge project. Shanghai Construction Group. invited Polymaker to join this project from the beginning to help develop a custom ASA 3D printing material for the bridge. Throughout the process, through multiple tests and experiments, Polymaker mastered ASA’s properties, mixing formulas and manufacturing techniques. As a result, PolyLite™ ASA gains several advantages over other ASA filaments. Polymaker’s engineers have developed an ASA filament with exceptional interlayer adhesion. PolyLite™ ASA exhibits superior ply bonding characteristics compared to similar products.

There are no reviews yet.