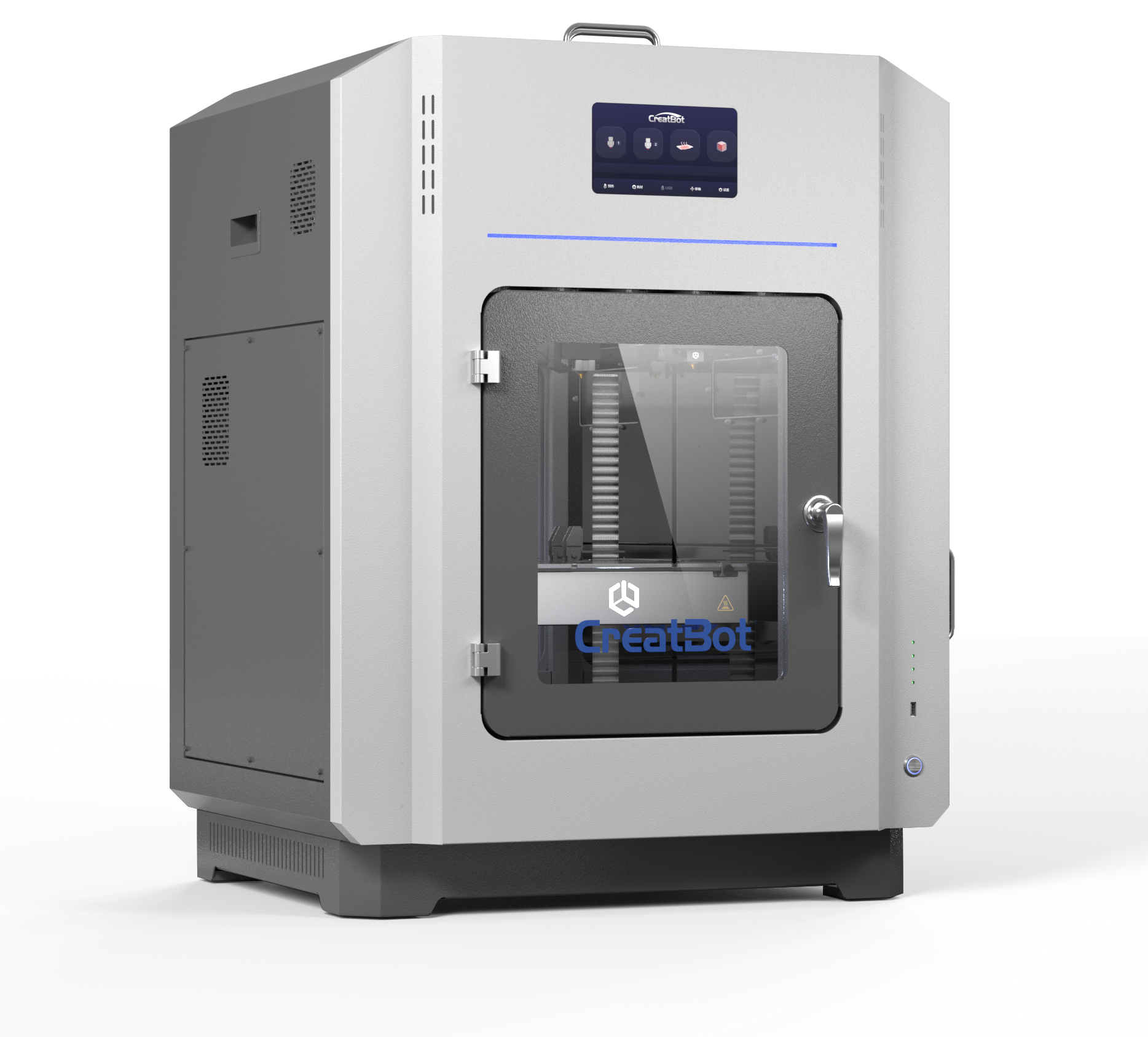

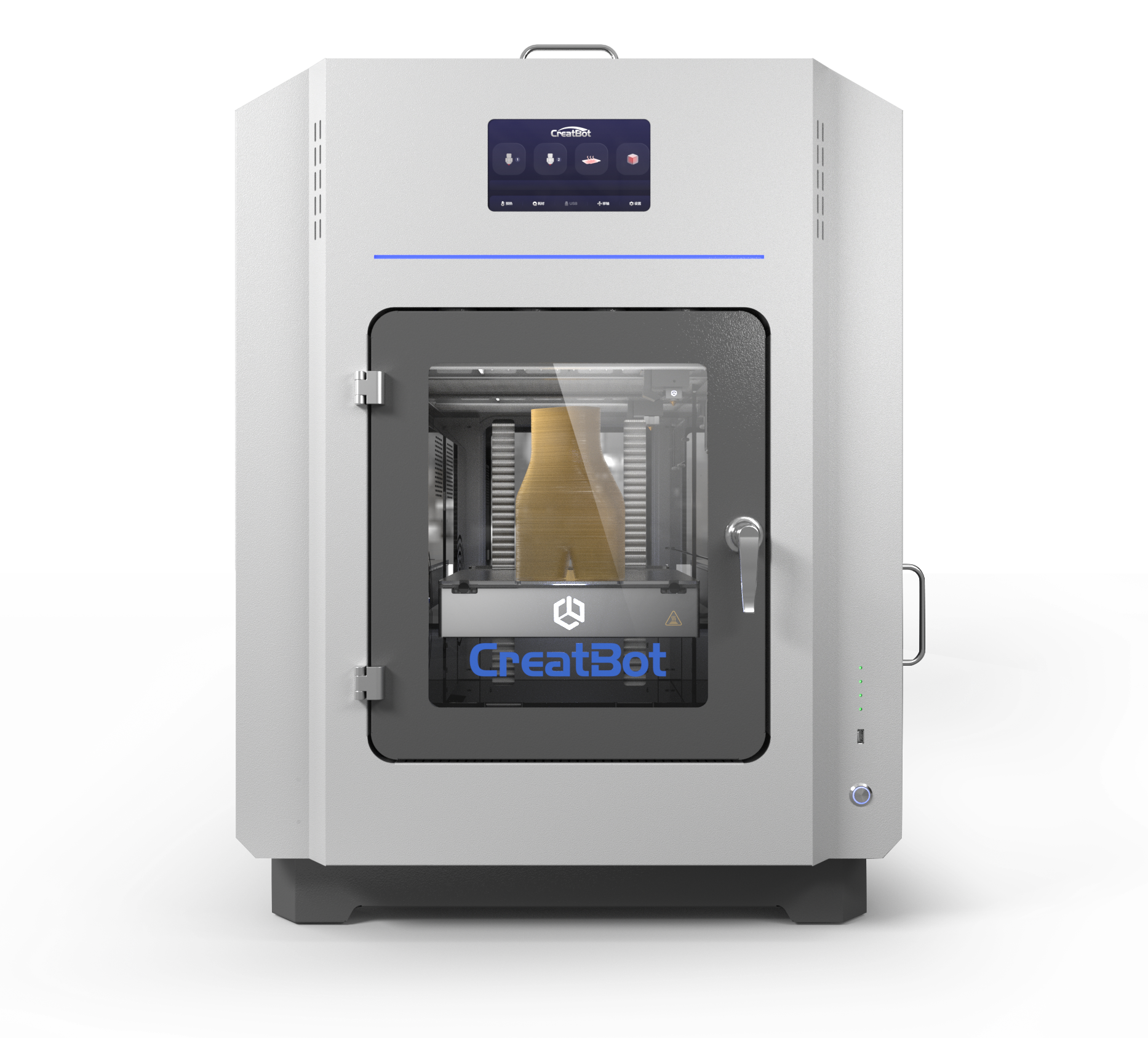

PEEK-250 CreatBot

Overview

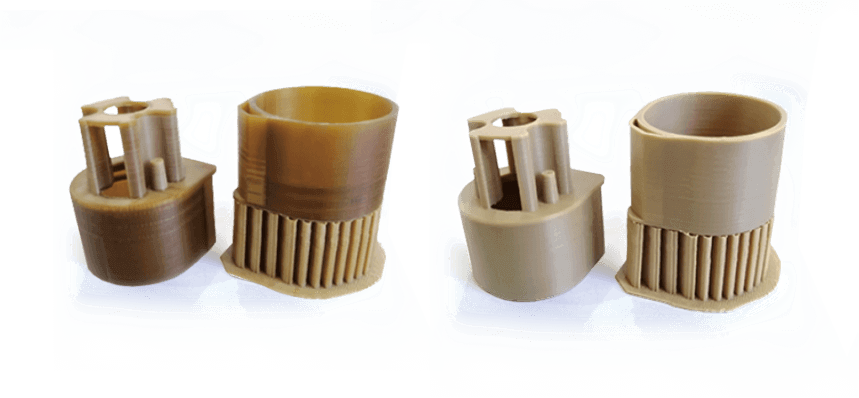

The CreatBot PEEK-250 is a professional ultra-high temperature FDM 3D printer specifically designed for printing with technical materials such as PEEK, PEI (ULTEM) and other high temperature polymers. It is among the first desktop printers with an enclosed chamber reaching up to 200 °C, which provides direct annealing after printing in the same environment

Why is a 180 °C hot chamber so important?

An ambient temperature of 180 °C is required for effective annealing of PEEK material.

This means that printed PEEK patterns can be heat treated directly in the device – without removal or cooling.

✔️ Key Benefits:

- No need to remove the model: adhesion to the platform is maintained and deformation of the base due to internal stress is avoided.

- No thermal shock: Avoids abrupt changes in temperature that can “lock” internal voltage into the model.

- Fully automated process: you can pre-set the heat treatment – for example 5 hours at 180 °C and then 5 hours at 120 °C.

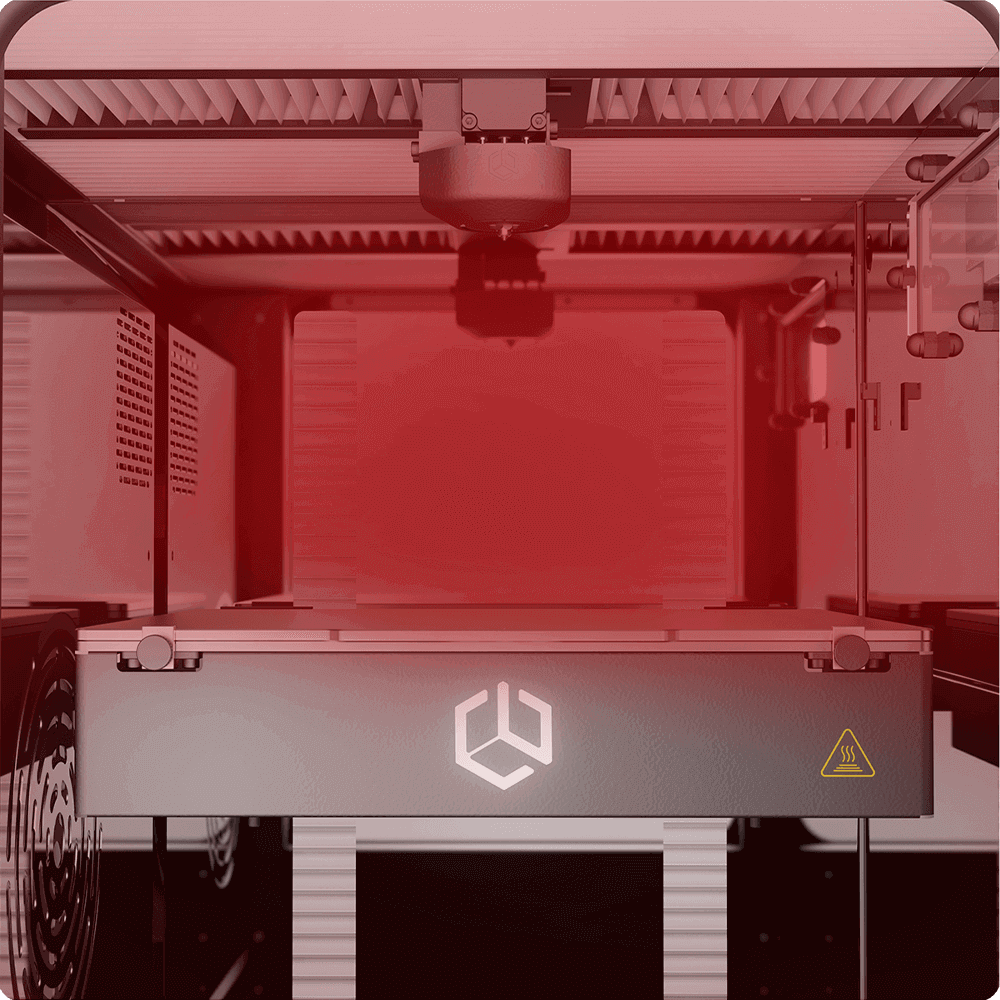

200 °C Thermally uniform chamber

A specially designed spoiler allows the hot air in the chamber to circulate 360°, ensuring even heating at every point.

This ensures uniform crystallization of the polymer material pattern at any angle and perfect geometry during forming.

Main features

Temperature capabilities

-

Nozzle: up to 480 °C

-

Platform: up to 200 °C

-

Chamber: up to 200 °C, heats to 180 °C in about 20 min

-

The surface of the outside of the chamber remains ≤ 40 °C after 5 h of heating

Print volume

-

Build volume: 250 × 250 × 300 mm

Extruder and printing

-

Extruder: Direct-drive with double-toothed silicon carbide, wear resistant

-

Nozzle diameter: standard 0.4 mm (optional 0.3-1.0 mm)

-

Speeds: optimum speed 55 mm/s; maximum 180-200 mm/s

Supported materials

Suitable for:

-

Engineering polymers: PLA, ABS, ASA, PC, Nylon, PETG, PVDF, carbon fiber

-

High temperature: PET-CF/GF, UltraPA, PPSU

-

Super materials: PEI (ULTEM series), PEEK, PEEK-CF, PEEK-GF, PEKK, etc.

Software Compatibility & Features

-

Software: CreatWare, Cura, Simplify3D, Slic3r

-

Operating systems:Windows, macOS

-

📂 Supports STL, OBJ, AMF, G-code

-

Special Features:

-

Power failure recovery

-

Missing filament tracking + auto pause

-

Direct annealing after printing function – sets the post-print temperature mode (e.g. 180 °C x 5 h → 120 °C x 5 h) without separating the model from the platform

-

Technical construction

-

Chamber: fully enclosed with 3-layer insulation and active door cooling – external surfaces remain ≤ 40 °C

-

Platform: PCB aluminium + PEEK coating; natural flatness 0.05 mm, at 180 °C remains ≤ 0.1 mm – no need for levelling

-

Positioning accuracy: XY = 0.0127 mm; Z = 0.00125 mm

Power supply and physical dimensions

-

Input voltage: 200-240 V, 20 A

-

Power: 2,500 W

-

7″ colour touchscreen with multilingual interface

-

Control: USB disk or USB connection

-

Dimensions: 630 × 555 × 815 mm; Weight: approx. 120 kg

Benefits and advantages 🧰

-

High thermal stability – direct annealing after printing, without removing parts

-

Printing with materials up to 500 °C – including carbon and glass fibre composites

-

Use and safety – passive outdoor temperature, active cooling system

-

Full post-press automation, saves time and stress on material

-

No distortion in hot mode – construction and insulation work in sync

Table with technical specifications

| Feature | Parameter |

|---|---|

| Print volume | 250 × 250 × 300 mm |

| Nozzle max. temperature | 480 °C |

| Platform max. temperature | 200 °C |

| Chamber max. temperature | up to 200 °C |

| Optimal/max speed | 55 mm/s / 180-200 mm/s |

| Filament diameter | 1.75 mm |

| Nozzle | 0.4 mm (variants 0.3-1.0 mm) |

| Positioning accuracy | XY = 0.0127 mm; Z = 0.00125 mm |

| Power | 200-240 V, 20 A; 2,500 W |

| Screen | 7″ touch (Full color, multilingual) |

| Interface | USB drive/USB connection |

| Dimensions / Weight | 630 × 555 × 815 mm / 120 kg |

| Supported software | CreatWare, Cura, Simplify3D, Slic3r |

| Supported materials | PLA, ABS, ASA, PC, Nylon… up to PEEK, PEI |

There are no reviews yet.