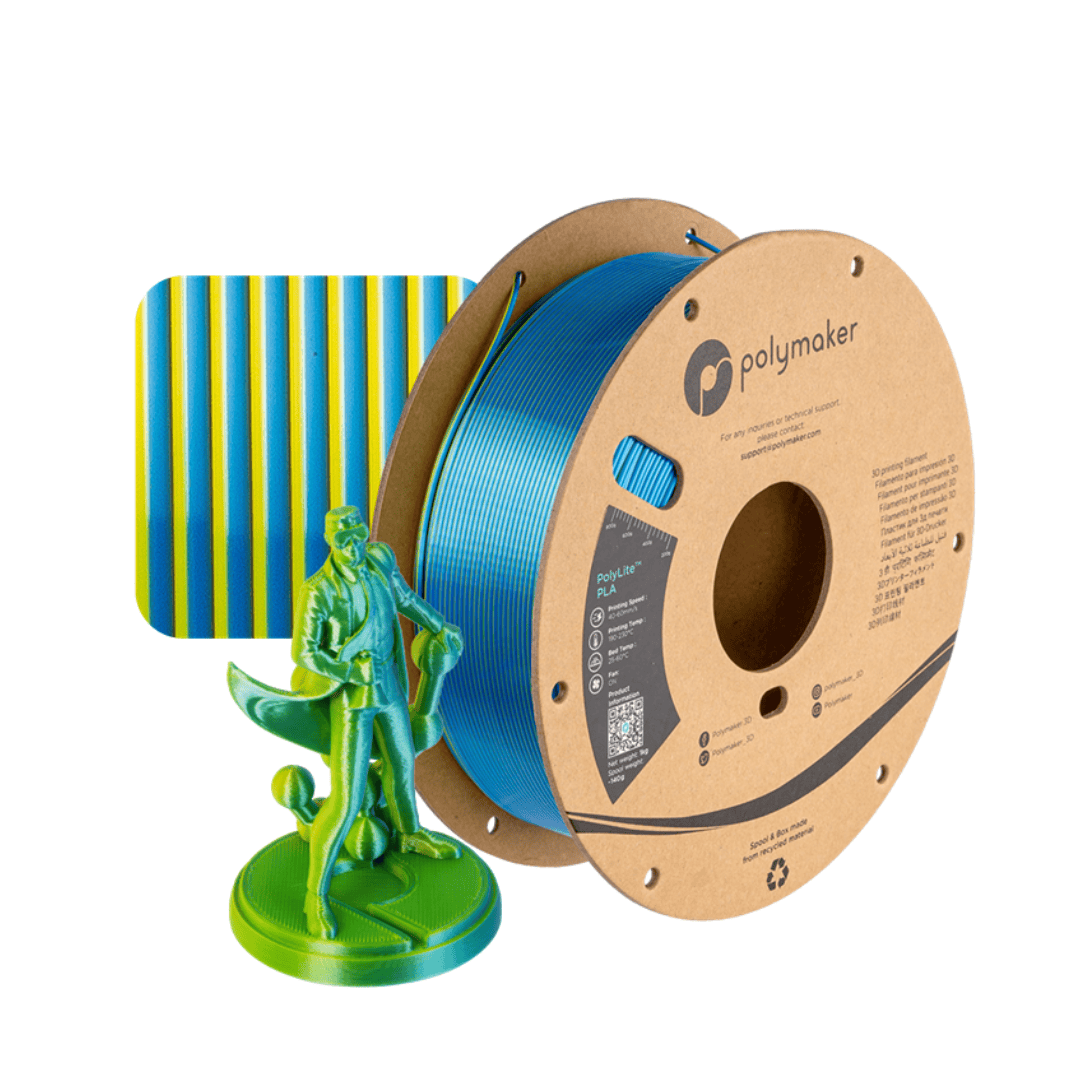

PolyLite PLA – Silk Yellow – Blue – Polymaker

View

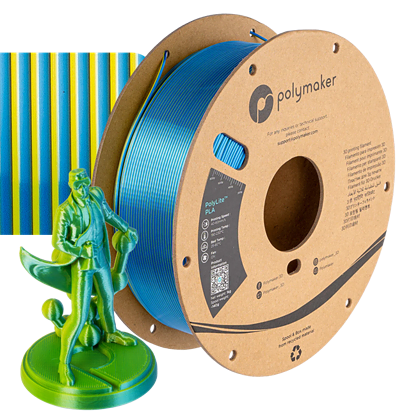

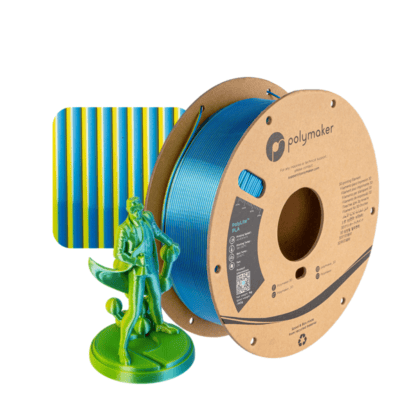

The high-quality, glossy and dichromatic PolyLite Dual Silk PLA prints two-color patterns with a dynamic color transition effect.

- High Quality Polymaker Silk PLA.

- Striking dichromatic/dual-colour filament.

- Glossy and silky surface finish.

- Easy to print.

- Cardboard spool and packaging (made of 100% recycled cardboard)

- Consistent color and tolerance(1.75 mm diameter +/- 0.03 mm)

PolyLite™ PLA Dual Silk is a dichromatic PLA silk filament for 3D printing that is produced in two different colors to give models a striking two-tone effect. It’s the perfect choice for creating unique, eye-catching multi-color prints with an elegant surface finish that hides the layers. Made from high quality materials, PolyLite™ PLA Dual Silk combines the luxury and elegance of silk with the flexibility and printability of Silk PLA.

Features

Dichromatic Silk Surface – PolyLite™ PLA Dual Silk is a high quality two-color filament that offers a beautiful and dynamic color transition effect for your 3D models. The silky finish of this filament is achieved without the need for post-processing and adds a smooth touch of elegance to your 3D models, making them suitable for a variety of applications such as jewelry, home decor or fashion accessories.

Compatibility Considerations – PolyLite™ PLA Dual Silk is an easy-to-print filament and is compatible with a wide range of popular extrusion-based 3D printers. (In some cases, bed heating may be required). With its excellent print quality and outstanding visual effect, PolyLite™ PLA Dual Silk PLA filament is the perfect choice for your next remarkable 3D printing project.

Easy to print – PolyLite™ PLA Silk works well with many common printing surfaces and does not require a strictly heated bed, but may be recommended on some surfaces or build plate geometries for better results (up to 60°C).

Uncompromising quality – PolyLite™ PLA Silk is a PLA blend made with the highest quality ingredients, including Ingeo® from Natureworks. Natureworks is a leading US-based global supplier of biopolymers with a portfolio of high-quality PLA feedstocks made from rapidly renewable plant resources. Combining Polymakers’ innovative R&D technologies, blending and extrusion systems with Natureworks’ Ingeo® resins yields a reliable 3D printing filament for printing beautiful and accurate models.

Please note that it is not possible to make a PLA silk filament with thermal creep resistance; this is why PolyLite™ PLA Dual Silk does not have the Jam-Free™ technology implemented in other PolyLite™ PLA filaments. This may affect compatibility with printers that suffer from thermal creep, and for these users we recommend considering PLA filament that features Jam-Free™ technology. On some printers, it may be possible to solve thermal creep problems with a different hot end design.

Print settings

| Nozzle temperature | 190°C – 230°C |

|---|---|

| Pad temperature | 25°C – 60°C |

| Surface material for construction | Works well with most substrates, e.g. glass, Blue Tape, BuildTak® |

| Surface treatment | Usually not required. Some surfaces work well with Magigoo or PVA adhesive. |

| Cooling fan | ON |

| Print speed | 40 mm/s – 60 mm/s |

| Recommended support materials | Single extrusion: Self-support

Double extrusion: PolyDissolve™ S1 or PolySupport™ |

Note: Based on 0.4 mm nozzle. Printing conditions can vary between printers and nozzle diameters.

Tips for printing dichromatic filaments:

1. Dichromatic/two-color filaments print best when all outer perimeters of the part are printed in the same direction for each layer, but not all slicers do this by default.

2. PolyLite Dual Silk PLA is carefully wound to ensure proper color alignment on the spool. To achieve the best result, make sure the filament does not twist in the feed path. If the filament twists during printing, the position of the two colors will shift during printing, resulting in a banding effect. Some users find this effect desirable, while others do not. Some level of twisting is common for most 3D printers on the market, but excessive twisting may be more likely on some printers depending on the spool assembly, hot end, and extruder design. Using a high quality extruder with dual gearing and direct drive and mounting the spool in a straight position that prevents twisting can help reduce this banding effect.

3. Smaller melt zones are better for dichromatic/two-color filaments. This effect occurs because our 3D printers print with a laminar flow and so the two colors do not mix. Volcano type hot nozzles or CHT type nozzles can cause mixing which reduces the visual effect of the dual color.

4. It may be helpful to print an alignment coin to show you exactly where the color change will occur. The angle will be different for each printer setting, but we have found that if the printer and spool remain in the same orientation, the alignment does not change from spool to spool.

Tips for printing with silk filament PLA

1. It is not recommended to use Silk PLA on printers that suffer from thermal creep.

2. Under normal conditions Silk PLA should print with a high gloss, but at high printing speeds Silk PLA may not melt properly, resulting in a dull or inconsistent surface finish. Using a slower speed for the perimeters, limiting the volume flow to 8cc/sec and trying a slightly higher nozzle temperature can help.

Product Specifications

| Weight: | 1kg |

|---|---|

| Type of material: | Silk Dual PLA |

| Density: | 1.20 (g/cm3 at 21.5˚C) |

Compatibility

PolyLite™ PLA Silk has been developed with compatibility in mind to print perfectly on a wide range of 3D printers. Although PolyLite™ PLA features Jam-Free™ technology, it is not possible to implement this technology in silk filaments such as PolyLite™ PLA Dual Silk.

Of course, with thousands of unique 3D printer models on the market, we can’t guarantee that every type of filament will work with every 3D printer. Experience with cutting machines and adjusting settings is always required to get the most out of a material. Before embarking on an ambitious project, we always recommend printing some known calibration tests to build or make adjustments to the filament profile.

If your printer suffers from thermal creep and has difficulty printing other brands of PLA or silk PLA due to jamming associated with thermal creep, PolyLite™ PLA Dual Silk may pose a jam risk to your extruder.

Technical data

All test specimens were printed under the following conditions: Nozzle temperature = 220˚C, build plate temperature = 40˚C, leachate = 100%, cooling fan = on

All specimens were conditioned at room temperature for 24 hours prior to testing.

THERMAL PROPERTIES

| Values | Test method | |

| Glass transition: | 56°C | DSC, 10°C/min |

| Heat deflection temperature: | 0.45MPa – 61.1°C 1.8 MPa – 59.3°C |

MECHANICAL PROPERTIES

| Values: | Test method: |

|

| Jung’s module (X-Y) |

3098 ± 147 MPa | ISO 527, GB/T 1040 |

| Tensile strength (X-Y) |

51.5 ± 1.9 MPa | ISO 527, GB/T 1040 |

| Bending force (X-Y) |

104 ± 1.3 MPa | ISO 178, GB/T 9341 |

| Sharpie impact strength (X-Y) |

3.46 ± 0.32 kJ/m2 | ISO 179, GB/T 9343 |

Typical values presented in Polymaker data sheets are for reference and comparison only. Due to the nature of 3D printing, they should not be used for design specification or quality control purposes.

Storage and drying

All plastics are hygroscopic, meaning they absorb moisture from the air, which can affect the print quality and strength of printed parts. How quickly this absorption occurs depends on the material and the environment. Polymakers PolyLite™ Dual Silk PLA fibers are dried and packaged in a vacuum sealed bag with desiccant to ensure the best print quality. When not in use, PolyLite™ Dual Silk PLA should be stored away from sunlight and sealed in the packaged resealable bag.

Although filaments can be dried, drying will accelerate the aging process of the plastic, making it more brittle over time. Preventing moisture from being absorbed by the filament in the first place is the best solution to keep your filament at its maximum potential. For long-term storage, we highly recommend storing in a sealed container with a desiccant dryer that reduces relative humidity to 10-20% RH.

If you hear popping sounds and notice that the surface quality of your print is uneven or the color is not consistent, this is a likely indicator that the filament has absorbed too much moisture. PolyLite™ Dual Silk PLA spools can be dried with a Polymaker PolyDryer™, or other filament dryer using power level 1. Alternatively, if you have a convection oven that is accurate at low temperatures, users can dry the filament in a pre-heated convection oven at 55˚C for up to 6 hours. Results may vary depending on the accuracy of your oven, so please use caution.

Frequently Asked Questions

Q: Does PolyLite™ PLA Dual Silk have Jam-Free™ technology?

A: To achieve a silky surface finish, PolyLite™ PLA Dual Silk does not feature the Jam-Free™ technology used in PolyLite™ PLA and other Polymaker PLA filaments.

Q: Does silk PLA print the same way as regular PLA?

A: Silk PLA is a blend of PLA with other plastics and is considered a high quality and silky surface finish, with the settings and printer playing a large role in the end result. As with any modified formula or blend, the best settings and capabilities of Silk PLA will differ from those of PLA, but both Silk PLA and regular PLA have very similar settings, allowing Silk PLA to offer the ease of use that PLA is known for.

Q: Can PLA be printed in large scales without deforming?

A: One of the advantages of PLA is the ability to print large parts with excellent dimensional stability; we have many customers who print large full-scale projects from PolyLite™ PLA Dual Silk. Please note that while PLA materials do not warp in most situations, printing with poor adhesion on the first layer can cause any material to warp, and printing or heating the bed too hot can cause any PLA filament to crystallize quickly, creating internal stress and warpage.

Q: What auxiliary materials can I use with this product?

A: Polymaker’s PolyDissolve™ S1 or PolySupport™ are the recommended support filaments for PolyLite™ PLA Dual Silk. If your 3D printer is not equipped to handle many materials, a self-supporting filament can be used.

Q: Do I need to rewind this thread if I want to use it with another spool?

A: We strongly advise you not to manipulate the product by rewinding. All Polymaker filaments are wound with tension but without strain. Rewinding completely rearranges the curvature of the coil and this tension over time can cause most plastics to catastrophically break. If for some reason your printer is blocked from mounting smaller than standard size spools, there may be safe print adapters or external mounting solutions available.

Applications

PolyLite™ Dual Silk PLA combines the luxurious look of silk with the vibrant two-tone effects of dichromatic PLA. Whether you’re a professional designer, hobbyist or artist, this dual-color silk PLA fiber is sure to give your 3D models a professional, high-quality look and feel.

Two-color transparencies are typically used to print a wide range of common print projects for your home or small business, including:

- Figures.

- Toys.

- Decorative patterns and vases.

- Custom trophies and medals.

- Brilliant gifts for friends and family.

- Accent colour for assembled 3D models.

- Models that require a metal finish.

- Metallic or shiny elements for cosplay.

- Scale models and architectural models.

Compared to PolyLite™ PLA, PolyLite™ Dual Silk PLA has slightly different mechanical properties and layer adhesion. Like other PLA-based filaments, Silk PLA has low heat resistance, so it is not recommended to print Silk PLA for applications that may be exposed to high temperatures.

There are no reviews yet.