PETG Premium – Transparent Orange – Spectrum

High transparency and chemical resistance

Spectrum PET-G Premium is the second most popular material for desktop 3D printing. A major advantage of Spectrum PET-G Premium is its near-zero shrinkage and low moisture absorption compared to other thermoplastics used for FDM/FFF 3D printing. Products manufactured with PET-G retain stable properties over a long lifetime. Spectrum PET-G Premium combines the advantages of PLA and ABS. It also provides virtually seamless printing and exceptional adhesion between layers.

Products printed with Spectrum PET-G Premium transparent inks have a high crystalline phase content, allowing the effect of near-transparency in a small number of outer perimeters of additively manufactured products. The pellets and pigments used in the manufacture of Spectrum PET-G Premium are approved for food contact.

Regarding the other properties of Spectrum PET-G Premium, it should be noted the good creep resistance under constant load conditions. It is due to the very good cohesion between the layers of the applied material. This results in a much lower mechanical anisotropy in the printed products, which means that for each manufacturing direction the mechanical properties differ less than for other thermoplastic materials designed for 3D printing.

Key Features:

- high transparency compared to other additive manufacturing materials

- very good mechanical properties in terms of hardness, toughness and impact resistance

- temperature resistance HDT – 69°C

- Vicat softening point – 78°C

- chemical resistance

- high dimensional accuracy

- combines the advantages of PLA and ABS

- exceptional adhesion between layers

- odourless seal

Applications:

- visual and functional prototyping

- suitability testing

- conceptual models

- production aids

- production of translucent housings and backlit parts for various boards and signs

The very good mechanical properties of Spectrum PET-G Premium, combined with its chemical resistance, determine the application of this material for the production of products with relatively high dimensional accuracy and stability of shapes and mechanical properties. Accordingly, these are primarily gears and plain bearings subjected to relatively high static loads in aqueous environments. PET-G is also used for the production of translucent housings and back-illuminated parts for various boards and signs

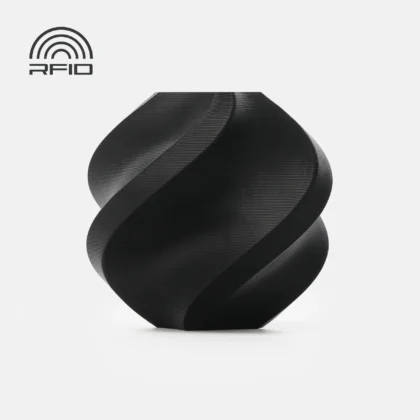

Packaging

The fiber is wound on a clean, transparent spool. Each spool contains information on the material type, diameter and recommended printing temperature. The filament is vacuum packed with a moisture absorber. All product is packaged in Spectrum Filaments’ original, folded packaging.

General information

- Material group: PET-G

- Colour: Orange

- Colour spectrum name: Transparent Orange

- Diameter: 1,75 mm

- Dimensional tolerance: ± 0.03 mm

- Check your reel – review the diameter stroke along the entire length of the reel: YES

- Density: 1,27 g/cm³

- Net weight: 1000g

- Total weight: 1400g

Recommended print settings

- Printing temperature – 230-255°C

- Warm bed – necessary

- Heated bed temperature – 60-80°C

- Print speed – 40-120 mm/s

- Closed chamber – Not necessary

Reel dimensions

- Outer diameter – 200 mm

- Width – 67 mm

- Internal diameter – 52 mm

- Weight of empty reel ± 250g

There are no reviews yet.