H2D Bambu Lab

Features

- 3D printing with two nozzles and many materials

- Optional 40W/10W laser and cutting module

- 350*320*325 mm³ printing volume

- NON-LASER version WITHOUT AMS

- 5μm resolution – Optical motion calibration

- Closed loop servo extruder

- Nozzle heating up to 350°C and active chamber up to 65°C

We plan to release a laser upgrade kit for the non-laser version of H2D.

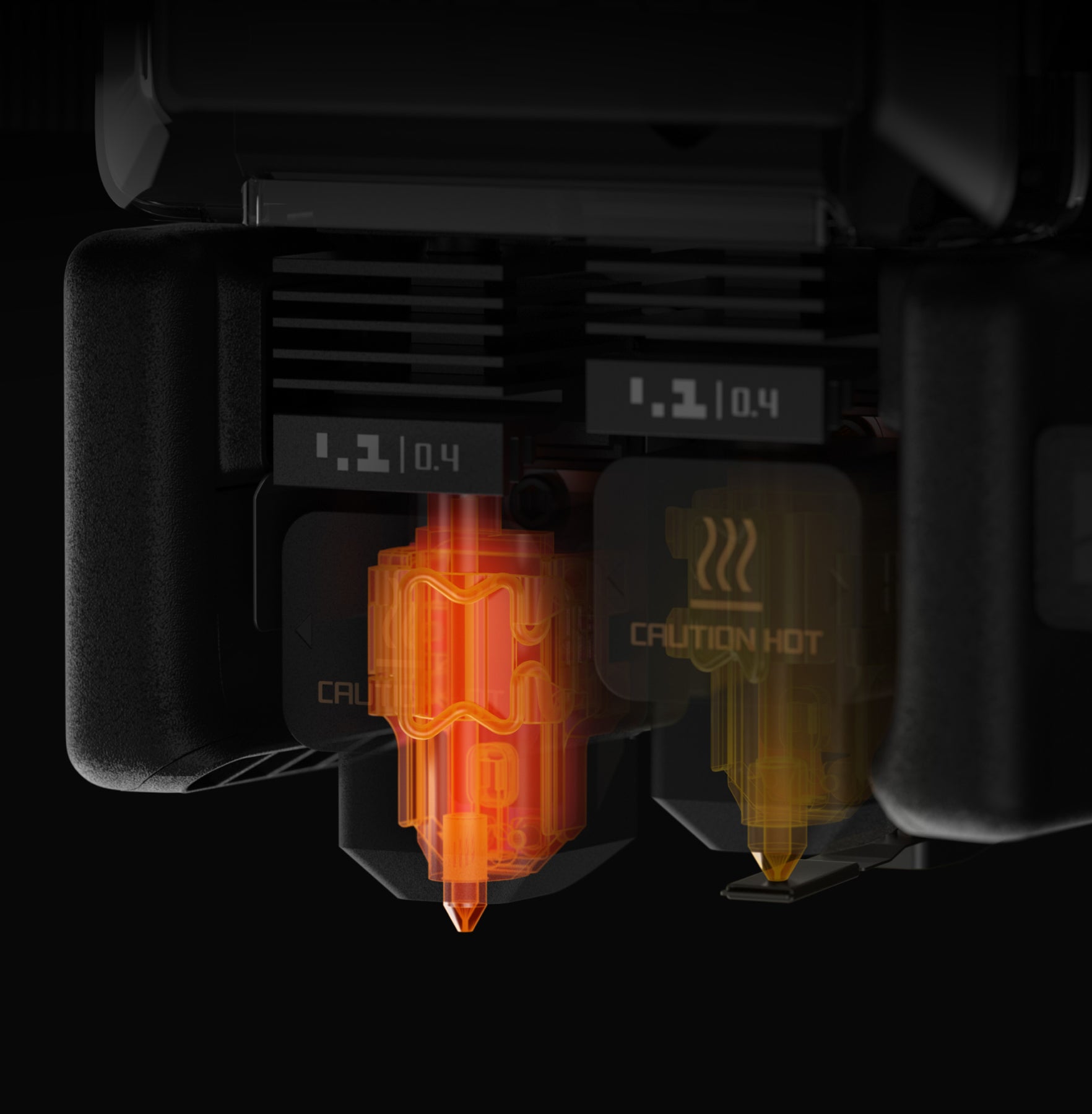

Explore the possibilities of dual nozzles

Printing of various materials

Flexible and rigid, cheap and exotic materials in one print

Combine flexible and rigid materials in a single print to create impressive interlocking structures and innovative designs that are beyond traditional manufacturing. Combining high-performance materials with standard materials further reduces costs and increases material efficiency by using premium materials only when needed.

Specialised support material

Perfect supports with minimal waste, purification and recharging

Pad printing is no longer a headache. With H2D’s dual nozzle setup, one nozzle can be reserved for special support material, allowing secure printing and a perfect maintenance interface.

Efficient multi-colour printing

Fast and efficient multi-colour printing

Dual nozzle printing reduces blow cycles for multi-colour prints. H2D’s intelligent algorithms optimize filament usage, maximizing dual nozzle efficiency to save time and materials.

All-in-one solution for personal production

Colouring with marker

Drawing and writing

Real-time spatial alignment

What you see is what you get

H2D’s BirdsEye camera, combined with computer vision algorithms, provides top alignment accuracy down to 0.3 mm. This advanced spatial alignment allows users to place the toolpath in the correct position on the material – truly “what you see is what you get “*.

Automatic stacking

Maximize material efficiency, minimize waste

Using real-time images from the BirdsEye camera, Bambu Suite can automatically arrange your project according to the shape of the material, e.g. the leftover plywood from a previous project. This feature helps you get the most out of any material.

Don’t worry about safety – we’ve got you covered

- Laser Safety Windows

- Work and monitor laser projects safely without the need for glasses thanks to our safety windows.

- Air Purifier

- The optional air purifier ensures clean air even during indoor laser operation.*

Don’t worry about the settings – we’ve taken care of them

- Full automatic calibration

- With just one touch, automatic laser focus verification and material measurement is initiated, eliminating manual adjustments.

- Material CodeSync

- H2D automatically scans the QR code of your material to load the perfect preset.*

Big, fast, precise

Our secret weapon: Vision Encoder

50µm ultrafine motion accuracy*

The super-fine plate with visual encoder, combined with optical measurements with 5 μm resolution to track and correct for instrument head movement, allows the H2D to achieve consistent and reliable 50 μm distance-independent motion accuracy throughout the entire workspace, which is an order of magnitude better than that of its predecessor. (*Visual encoder sold separately)

King size work area

Free yourself from size restrictions

With a print size of up to 350mm×320mm×325mm*, creating large-scale projects has never been easier! From laser engraving large objects to printing huge models, the expanded capacity enables you to bring even your most ambitious ideas to life.

MAX ->

<- Single nozzle

Double nozzle ->

<- X1 Carbon

Chamber heating at 350°C and 65°C

Unleash the full potential of high-performance materials

Equipped with active chamber heating up to 65°C and a high-temperature heater reaching up to 350°C, the H2D provides precise closed-loop temperature control. This advanced system effectively eliminates distortion and warpage in high-performance materials, ensuring superior bonding of layers and maximizing their full potential.

A true high-flow heater*

Easily and consistently print at 600 mm/s

H2D’s purpose-built high-flow hotend delivers reliable, high-speed printing at 600 mm/s. Designed for consistent throughput, it eliminates flow limitations in the print environment, allowing continuous high-speed printing regardless of print size or complexity.*

DynaSense extruder

Intelligent sensor for precise extrusion control

Bambu Lab’s patented PMSM servo architecture creates an intelligent extrusion control system. It implements 20kHz torque/resistance sampling and position to dynamically modulate electromagnetic torque vectors. Extrusion stabilization and detection of filament grinding and clogging.

A smarter and safer experience

Nozzle chamber

Extrusion monitoring in the nozzle tip

H2D features a camera with a nozzle and a macro lens with artificial intelligence. This intelligent monitoring system continuously tracks extrusion patterns, immediately detecting material build-up, filament deviations and extrusion failures.

Plugging of the nozzle

Printing in the air

Spaghetti

Control flight before AI intervention

Peace of mind with every print

Before each duty cycle, the H2D vision system runs a comprehensive pre-flight checklist.

- Camera integrity scanning performs dirt detection on the entire printing surface.

- Hardware Configuration Audit- instantly recognizes nozzle dimensions and build plate properties.

- Digital-Physical Alignment – performs an automatic check of the correspondence between the detected hardware specifications and the active parameters of the cutter.

SOTA Thread Monitoring

15 sensors on one thread

Unlike previous systems with single filament leak detectors, H2D features comprehensive material flow monitoring. All the way from the AMS to the nozzle, 15 strategic sensors form an intelligent network that continuously monitors five key parameters: feed rate, tension, filament tip location, extruder thermal environment and extrusion dynamic pressure. This creates an industry-leading filament behavior control system.

All-in-one custom manufacturing hub

Integrated 3D printing, laser engraving/cutting and digital cutting/printing into a single platform.

A revolutionary increase in precision

An order of magnitude higher motion accuracy.

Double nozzle, double versatility

Fast and efficient printing on a variety of materials!

Simplicity powered by AI

4 computer vision cameras*, 36 sensors, 2 servomotors, united by a complex algorithm for your simplicity.*

Next Generation Filament Management

Drying, feeding and storage in one package.

Endless possibilities of

personal production

Hub for personal fabrication

H2D is not just a 3D printer, it adds laser engraving and cutting, digital cutting and drawing to your studio, unlocking new creative possibilities.

Laser

10W and 40W 455nm laser for engraving and cutting

Digital cutting

Precision cutting of various materials

Drawing with marker/chemical

Drawing and writing

Solid core laser machine

High power 455 nm laser

Cut 5mm plywood with a 10W laser and 15mm plywood with a 40W laser.

Air Assist

Improve surface quality by directing high-speed air to cool the laser path, providing cleaner, more precise results.

Non-contact 3D mesh*

Advanced optical height measurement creates a detailed 3D mesh without physical contact, enabling precise laser work on curved surfaces.

Rotary attachment

Expand your capabilities with the rotary attachment that allows laser engraving on cylinders, spheres and rings.*

Laser Safety Windows

Work and monitor laser projects safely without the need for glasses.

Air Purifier

The optional air purifier ensures clean air even during indoor laser operation.*

Real-time spatial alignment

What you see is what you get

H2D’s BirdsEye camera, combined with computer vision algorithms, provides top alignment accuracy down to 0.3 mm. This advanced spatial alignment allows users to place the toolpath in the correct position on the material – truly “what you see is what you get “*.

Printing and cutting

Create colourful projects with ease

Instantly turn graphic prints into precise cuts. Design and print with Bambu Suite and your graphics printer, then use H2D to cut it. Its artificial intelligence camera automatically aligns the cutting path with the graphic, ensuring perfect registration with minimal effort.

Goodbye to manual laser focusing and thickness adjustment

Full automatic calibration

With just one touch, automatic laser focus check and material measurement is initiated, eliminating manual adjustments.

Material CodeSync

H2D automatically scans the QR code of your material to load the perfect preset.*

A revolutionary increase in accuracy

With a motion system that is 10 times more accurate, H2D greatly reduces the difficulty of adjusting designs and setups to accommodate standard components or to fit printed parts together.

Automatic compensation of holes/loop

Perfect fit, first time, every time – no adjustments needed*

Thanks to H2D’s improved motion accuracy and Bambu Studio’s specialized calibration for select Bambu Lab fillets, you can achieve a perfect fit with standard parts like a steel shaft every time – no more tedious distance adjustments required.

Double nozzle, <25 μm offset

Two nozzles that print as one

Our state-of-the-art nozzle reading technology ensures fast and reliable calibration by aligning the two nozzles before each print. Non-contact measurements are reliable and unaffected by nozzle contamination.

Nozzle pressure sensor and active flow compensation

Smooth surfaces, sharp edges

H2D uses both the extruder’s servomotor sensing capabilities and the nozzle’s high-resolution eddy current sensors to precisely control extrusion by measuring nozzle pressure and calibrating PA parameters for each filament, improving surface smoothness and edge sharpness.

Active vibration compensation

Silky smooth operation with lightning speed

To minimize ribbon artifacts during high-speed printing, H2D uses automatic vibration compensation. Using sensors on the tool head, the system calibrates parameters before each print for consistently smooth and stable results.

Floating legs on the flap

Isolate unwanted vibrations for better print quality

The H2D uses floating damper feet with a precisely tuned resonant frequency to effectively isolate the machine from desktop vibration. This vibration isolation system ensures consistent print quality even in the presence of external vibration sources.

Double nozzle

Double flexibility

Experience the mastery of mechanics and the full potential of multi-material printing with H2D’s innovative dual nozzle switching system. Lightweight, precise and reliable, it enables seamless material changeovers, unlocking a world of creative possibilities.

Full automatic offset calibration of two nozzles

No manual adjustment, no calibration tools

Enjoy seamless accuracy thanks to eddy current sensing technology that provides fast, non-contact and fully automatic offset calibration on two nozzles. This system is protected from nozzle contamination and eliminates the need for hand tools or guides, streamlining your workflow.

Perception determines intelligence

H2D is redefining sensor superiority in personal manufacturing. This technology orchestrator integrates a four-camera computer vision system* with a suite of 36 sensors harmonized through our patented neural algorithm – providing micron-level measurement accuracy, self-optimizing calibration protocols and real-time diagnostic intelligence.

Health Management System 2.0

Full support from start to finish

The HMS system uses sensors and cameras to fix printing problems using advanced logic similar to vehicle diagnostic codes. It provides clear and detailed troubleshooting instructions, allowing you to quickly resolve issues and get back to your creative work.

Emergency stop and loud beep

The H2D Laser Edition is equipped with a safety-compliant emergency stop and audible alarm, allowing users to quickly identify safety issues and easily stop machine operation.

Fully refractory chamber

The H2D features flame-resistant materials throughout its chamber, providing comprehensive passive fire protection.

Flame sensor

The H2D camera is equipped with flame sensors that can detect a fire immediately. In the event of a fire, it quickly sends warnings via push notifications and an audible alert, minimising potential risks.

Automatic fire extinguishing system*

An optional CO2 extinguishing system is available which works in combination with the flame sensor to extinguish the fire immediately, adding further peace of mind.

Multi-sensor closed loop temperature control

H2D features a closed-loop temperature control system for all heating components that continuously adjusts the temperature based on real-time sensor data. This ensures stable and precise temperature control, keeping the unit within optimal temperature ranges.

Adaptive air flow

Utilizing three mode-switching valves and an intake/exhaust chamber, H2D’s adaptive airflow system provides flexible air management for a variety of operational needs. The system intelligently switches between indoor and outdoor circulation and provides selectable air filtration or heating, solving challenges such as odors and dust from laser processing, smoke filtration from 3D printing, and chamber temperature control, offering a customized air quality solution for your personal manufacturing center.

Seamless connectivity to the cloud and off-grid isolation, your choice

H2D offers convenient cloud connectivity for remote control from any device. For security-sensitive applications, it also provides full offline functionality, ensuring physically isolated security. Users can manage the printer, send files and update firmware without an internet connection. In addition, developer mode allows access to the MQTT port for masters who want to integrate third-party components and software.*

Evolved AMS

The all-new 2nd generation AMS systems, including the AMS 2 Pro and AMS HT, feature brushless feed servomotors that significantly increase filament feed efficiency, accelerating multi-color and multi-material printing. Even better, the 2nd generation AMS introduces a filament drying feature with an active vent on a fully enclosed system, which significantly increases drying efficiency and maintains optimal filament conditions for extended periods of time.

Bambu Lab AMS 2 Pro

Bambu Lab AMS HT

Fast and intelligent drying of the filament

Electromagnetic air hole

Automated ventilation facilitates drying during drying and airtight sealing for weeks of quality printing.

Automatic rotation of drying

During the drying process, the filament spools rotate automatically to ensure more even drying.

RFID synchronisation

The AMS 2 Pro uses RFID to automatically match drying settings for official Bambu threads without the need for manual input.

Increase the speed! Faster printing from multiple materials!

Powerful synchronous servomotor with permanent magnets Bambu speeds up the feeding of the threads by 60%.

Average saving of 10 minutes per 100 thread changes

Faster multicolour printing

Evolved, polished design details

Tool-free access to thread tubes

Removing a frayed strand from a first generation AMS requires removing all spools and disassembling the housing with two screws, which takes 3-5 minutes. In contrast, the AMS 2 Pro offers direct, tool-less access to the threaded tubes on top.

Ceramic entrance

Vickers 1200 hardness ceramic filament entries significantly increase durability.

Why do you need a universal production centre?

Unlock new creative possibilities with hybrid processes

Space-saving all-in-one machine: Reclaim your workspace

One machine, the value of four

H2D specifications

| Product | Specification | |

| Printing technology | Fused deposition modelling | |

| Body | Volume to build (W*D*H) | Printing with one nozzle: 325*320*325 mm³ Printing with multiple nozzles: 300*320*325 mm³ Total volume for both nozzles: 350*320*325 mm³ |

| Chassis and hull | Aluminium, steel, plastic and glass | |

| Laser Safety Windows | Equipped with Laser Edition, normal H2D can be upgraded via Laser Upgrade Kit | |

| Pump for air assistance | Equipped with Laser Edition, normal H2D can be upgraded via Laser Upgrade Kit | |

| Physical dimensions | Physical dimensions | 492*514*626 mm³ |

| Net weight | 31 kg | |

| Print head | Hotend | All metal |

| Gear wheels | Hardened steel | |

| Nozzle | Hardened steel | |

| Maximum nozzle temperature | 350 °C | |

| Nozzle diameter included | 0.4 mm | |

| Maintained nozzle diameter | 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm | |

| Diameter of the filament | 1.75 mm | |

| Extruder motor | Bambu Lab high precision permanent magnet synchronous motor | |

Frequently Asked Questions

1. Can H2D be upgraded to H2D Laser Edition?

The laser full combination in the H2D has a built-in air pump and air tube on the back of the printer and is pre-installed with a BirdsEye camera. The front door, left and right side windows for laser protection and the top cover are designed with laser protection. The packing list includes a laser module, a cutting module, a fume extraction tube and adapter to it, and an emergency stop button.

We plan to release a laser upgrade kit for the non-laser version of H2D. The upgrade kit is expected to be released in June and will also provide installation instruction videos to help users perform the upgrade seamlessly.

It is important to note that the air pump in the upgrade kit is an external air pump that has a different installation structure than the built-in air pump in the complete kit. When using it, it can only be installed externally and connected to the machine via an air pipe.

2. Are the left and right chotendrons exactly the same?

Yes, the left and right chords have identical structures and materials and can be used interchangeably.

3.What is the maximum number of AMS 2 Pro and AMS HT devices that H2D supports? How many colors can it print at most at one time?

H2D supports a maximum of 4 AMS 2 Pro and 8 AMS HT connected simultaneously, for a total of 12 devices with 24 slots.

Because the H2D is a dual-hotend printer, and in the most extreme scenario all AMS can be connected to one hotend while the other hotend uses an external spool holder, it can support up to 25 colors.

4.Is H2D compatible with first generation AMS?

It is confirmed that the first generation AMS is fully plug-and-play compatible and can be used with H2D for multicolor printing, but does not support the AMS drying function.

Due to fundamental differences in the feed mechanism and buffer structure, H2D does not support AMS lite.

5.The AMS 2 Pro is directly connected to the printer via the 6-pin ports, so what are the two 4-pin ports on the back of the printer used for?

The two 4-pin ports on the back are reserved for future expansion accessories. For example, to upgrade a non-laser version of the printer to a laser version, one of these ports can be used to connect an external air pump.

6.Can I use the A1 series of H2D ? Conversely , can a H2D hotend be used on A1 series printers ?

Although the H2D series host is similar to the A1 host in structure , it is not exactly the same.

The H2D hosts are specifically designed for the H2D printer, offering optimized compatibility. For example, they support higher maximum volumetric flow rates, lower risk of clogging, more accurate nozzle offset calibration between left and right handhelds and automatic real-time detection of the type of chamber chute. Therefore, to ensure optimum print quality, it is strongly recommended not to use A1 hotends on the H2D printer.

Therefore , to ensure the best print quality, we strongly recommend not to use the A1 host for H2D printers.

Purchasing additional H2D hosts for use on A1 printers is possible. However, you will also need to use the silicone sock for the H2D hotend.

7.What is the difference between 10W and 40W laser modules? How to choose?

Both the 10-watt and 40-watt laser modules are blue light lasers that support machining a variety of materials including wood, rubber, sheet metal, leather, dark acrylic and stone. However, due to the differences in power and size, there are the following differences:

- Maximum cutting thickness (for basswood plywood):

- Laser module 10 W: 5 mm;

- 40W laser module: 4040: 15 mm;

- Maximum engraving speed (for basswood plywood):

- 10W laser module: 400mm/s;

- 40W laser module: 1000mm/s;

- Cultivable area:

- 10W laser module: maximum processing area: X310mm*Y270mm, maximum processing height 280mm;

- 40W laser module: maximum processing area X310mm*Y250mm, maximum processing height 265mm;

8.Is USB included as standard? What features are affected without USB?

The package does not include a standard USB flash drive. You can start printing normally without USB as the printer has built-in storage for the print files.However, without USB inserted, the following functions will be affected:

1. The recording and time-lapse functions cannot be turned on;

2. Printing cannot be initiated via the local network;

3. Print files cannot be sent to the storage machine via the studio;

4. Log files cannot be exported;

USB requirements: USB2.0 protocol or higher (actual minimum write speed must be greater than 10M/s), supported file formats are FAT32 and exFAT. The printer supports mounting on one USB only and cannot connect multiple USBs via a USB hub.

9.Why can’t you freely select a print host with the printer’s embedded files?

The host that will be used for printing is already defined when the model file is sliced. With embedded models, the right-hand chord is selected during the slicing process, so it is impossible to change the chord used for printing on the printer screen.When you slice the file in Bambu Studio and send the job to print, you can freely choose to use the left or right-hand chord. For some filaments, such as TPU and PPS/PPA-CF, it is recommended to use specific print hotends.

10. Will the smoke and dust generated by the laser affect the precision and lifespan of my printer?

The H2D is equipped with an efficient exhaust system that effectively removes smoke and dust generated by laser operations, significantly reducing pollution. During R&D, we conducted rigorous tests to ensure that with regular machine cleaning, the impact of smoke and dust on performance and accuracy is negligible. For detailed cleaning instructions, please see:[wiki]

11.How can I improve the success rate and print quality of TPU?

Due to the flexible nature of TPU filaments, there are some operational issues that can arise during feeding and printing. In order to make printing with TPU easier, we have created a dedicated guide on Wikipedia. Simply follow the instructions in the Wiki to successfully print with TPU filament:[Wiki]

12.Are there any special precautions I should take when using the laser function?

As laser processing involves the use of high energy lasers on potentially flammable materials, we strongly advise users not to leave the machine unattended during laser operations. Please maintain constant vigilance of the machine’s operating condition and ensure that there are no flammable or explosive materials in the machine’s surroundings. For more information, please see:[wiki]

There are no reviews yet.