Double sided smooth PEI pad for H2D – Bambu Lab

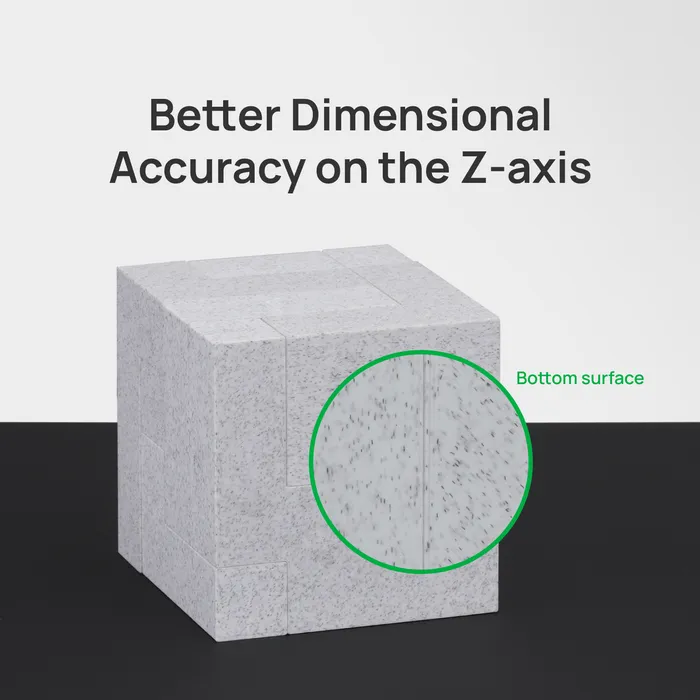

The use of smooth PEI backing contributes to improved Z-axis precision during the printing process, providing greater accuracy and consistency of vertical dimension. These qualities make the smooth PEI plate an excellent choice for printing parts that require a high level of precision fit, where precise alignment and tight tolerances are critical.

Smooth and matt surface finish

Using a specially selected PEI matte sheet can give a smooth and matte texture to the undersurface of the printed object, enhancing its overall appearance.

Compatible with various filaments

Compatible with various filaments

PEI allows printing not only with common materials such as PLA, TPU, PETG, but also with materials that require high temperatures, such as ABS and Nylon.

Reliable magnetic adhesion to prevent distortion

Reliable magnetic adhesion to prevent distortion

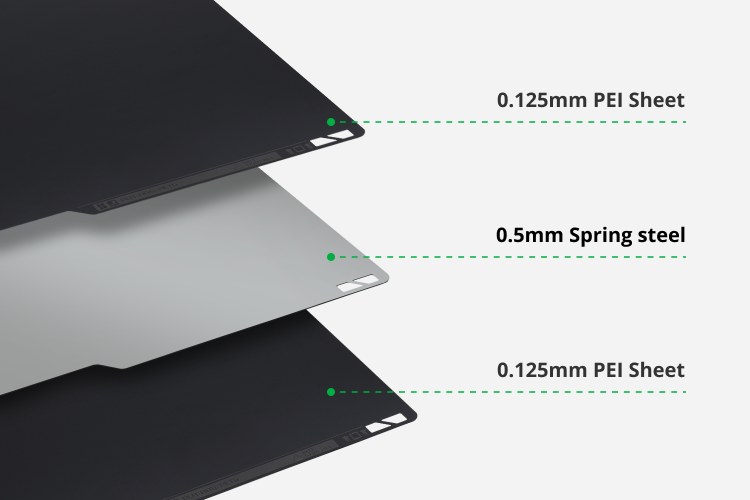

The Bambu Smooth PEI Plate is fitted with a 0.5mm thick spring steel plate that improves magnetic adhesion. This helps prevent distortion and ensure optimal print quality during 3D printing. It also helps when printing larger models with materials that are prone to warping, such as ABS, PC and nylon.

Considerations

Please note that with smooth PEI backing on A1, there is a greater risk of the backing creasing at the corners or the printed patterns separating from the plate. This is due to the thicker Smooth PEI applied to the backing which will increase the distance from the bed magnets and reduce magnetic attraction.

- If bubbles appear on the bottom of the sheet, heating it on the heating bed at a temperature no lower than 80 degrees for several hours may be helpful to remove the bubbles.

- The deposition of dust and grease on the build plate reduces adhesion. It is recommended to regularly clean the surface with detergent and water to maintain the best adhesion.

- Do not clean smooth PEI with acetone as it will damage the PEI surface.

- Always wait a few minutes before removing printed patterns to allow the plate to cool for easier removal of parts. This prevents damage to the substrate and ensures long product life.

- Gently sanding the surface with fine grit (600 grit is recommended) sandpaper can help restore adhesion.

- The Smooth PEI plate is considered a consumable part that degrades over time. The warranty only covers manufacturing defects and not cosmetic damage such as scratches, dents or cracks. Defective sheets on arrival are the only ones covered under warranty.

Recommended settings

Please note that other slider settings may need to be adjusted depending on the printed pattern and filament requirements.

| Materials: | Heating bed temperature | Is adhesive required? |

| PLA/PLA-CF/PLA-GF | 45~60℃ | No |

| PETG/PETG-CF | 60~80℃ | Yes |

| ABS (NOT also for A1 mini) | 90~100℃ | Yes |

| ASA (NOT also for A1 mini) | 90~100℃ | Yes |

| TPU | 35~45℃ | Yes |

| PVA | 45~60℃ | Yes |

| PC/PC-CF (NOT also for A1 mini) | 90~110℃ | Yes |

| PA/PA-CF/PAHT-CF (NOT also for A1 mini) | 90~110℃ | Yes |

| PET-CF (NOT also for A1 mini) | 80~100℃ | Yes |

Product Specifications

| Material: | Smooth PEI sheet + magnetic spring steel plate |

| Surface temperature resistance: | Up to 120℃ |

| Fatty: | Smooth PEI sheet- 0.125 mm Spring steel plate – 0.5 mm/0.4 mm |

| Usable print size: | 256*256mm 180*180mm |

| Pack Size: | 300*270*17mm 220*190*15mm |

| Package Weight: |

0.45kg 0.23kg |

There are no reviews yet.