PETG – CF – Green malachite – with spool – Bambu Lab

Product Features

- Less likelihood of nozzle blockage

- First-class printing surface

- Improved mechanical properties and high flexibility

- Comes with reusable main reel

- Diameter: 1.75 mm +/- 0.03 mm

- 1kg

Warnings for use

- 0,2 mm nozzle is NOT compatible

- Stainless steel nozzle not recommended

- Dry before use for highest print quality

- Compatible with AMS, AMS Lite is NOT ideal

Bambu PETG-CF

Bambu PETG-CF is a composite material composed of PETG and carbon fibre. The new formulation significantly improves print quality by reducing nozzle clogging and lump formation compared to traditional PETG. With the addition of carbon fiber, Bambu PETG-CF offers improved strength while maintaining good durability and a brilliant appearance. It is an ideal material for drone parts, racing models and various functional parts that require both high performance, especially impact strength, and an elegant appearance.

Premium print surface

The carbon fibers impart an advanced texture to the printed surface while maintaining the luster of the PETG itself.

Carbon fibre texture

Carbon fibers give a soft reflection, minimal layer lines and a unique delicate texture.

In contrast to the matt finish of PLA-CF, PETG-CF offers a glossy finish and thus offers another choice.

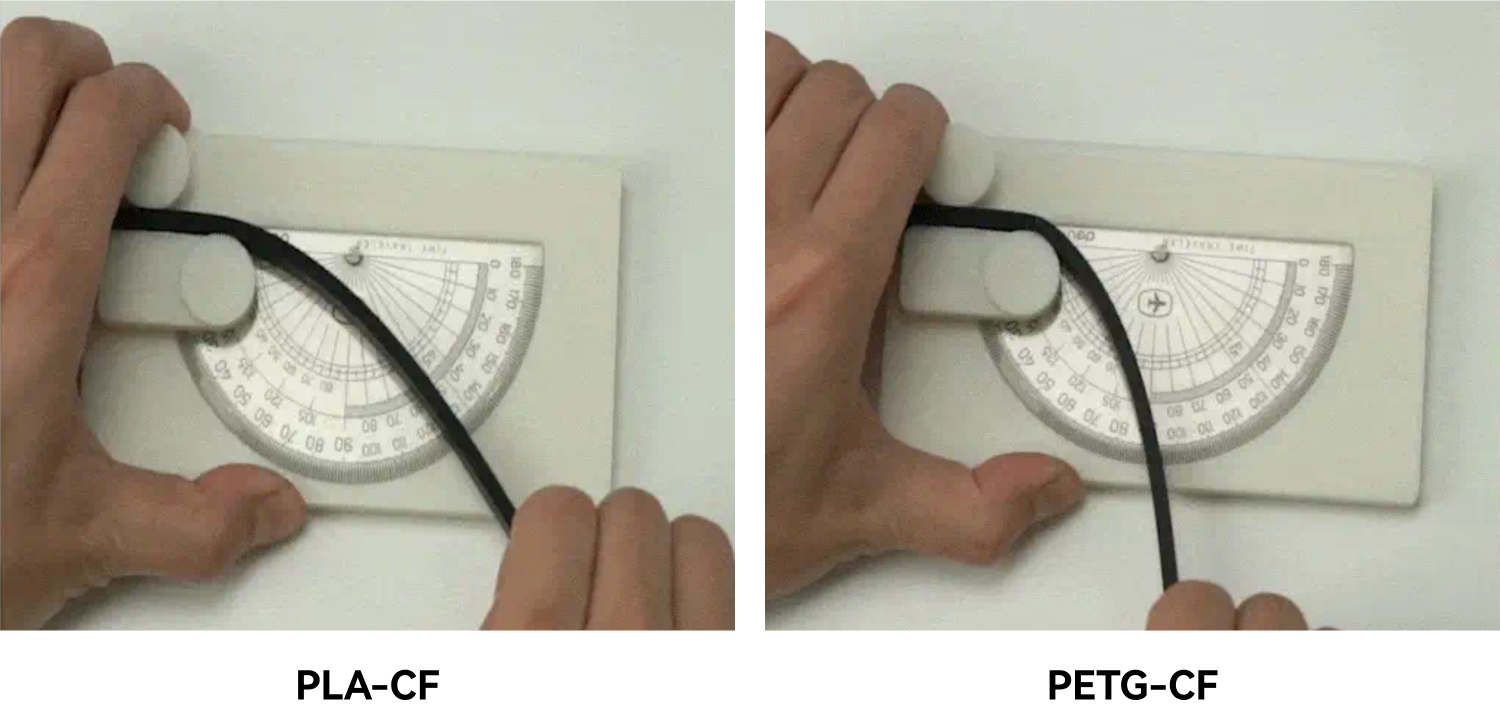

Strong performance of XY

The addition of carbon fibers also significantly increases the XY strength of PETG without compromising the bonding of the layers.

Comparison of parameters

| PLA-CF | PETG-CF | |

| Type of filament | Carbon fibre filling | Carbon fibre filled |

| Host Compatibility | Hardened steel (0.4, 0.6, 0.8 mm) | Hardened steel (0.4, 0.6, 0.8 mm) |

| Compatibility of the pad | Cool pad, High temperature pad, Textured PEI pad | Engineering pad, High temperature pad, Textured PEI pad |

| AMS compatibility | Yes | Yes |

| Surface | Matt | Glossy |

| Print speed | <250 mm/s | <200 mm/s |

| Durability (impact strength – XY) | 23.2 kJ/m² | 41.2 kJ/m² |

| Strength (flexural strength – XY) | 89 MPa | 70 MPa |

| Stiffness (flexural modulus – XY) | 3950 MPa | 2910 MPa |

| Layer adhesion (impact strength – Z) | 7.8 kJ/m² | 10.7 kJ/m² |

| Heat resistant(HDT, 0.45 MPa) | 55 °C | 74 °C |

High flexibility

Compared to other carbon fibre materials, Bambu PETG-CF has exceptional strength and is less prone to breakage under external stress and impact.

Compatibility of accessories

| Recommended: | Not recommended: |

|

| Backing: | Engineered backing, High temperature or Textured PEI backing | Cool Pad |

| Hotend: | Hardened steel nozzle (0.4/0.6/0.8 mm) | Stainless steel nozzle (0.2/0.4 mm) |

| Glue: | EcoFixy glue

Bambu liquid glue Glue -Stick |

/ |

RFID for smart printing

All print parameters are embedded in the RFID, which can be read via our AMS (Automatic Material System).

Load and print! No more tedious setup steps.

| Recommended print settings | |

| Drying settings (shock drying oven): | 65 °C,8 h |

| Printing and maintaining the humidity of the container: | < 20% RH (Sealed, with desiccant) |

| Nozzle temperature: | 240 – 270 °C |

| Bed temperature (with adhesive): | 65 – 75 °C |

| Print speed: | < 200 mm/ |

| Physical properties | |

| Density: | 1.25 g/cm³ |

| Vicat softening temperature: | 85 °C |

| Heat deflection temperature: | 74 °C |

| Melting temperature: | 225 °C |

| Melting index: | 19.3 ± 2.4 g/10 min |

| Mechanical properties | |

| Tensile strength: | 35 ± 5 MPa |

| Fracture extension rate: | 10.4 ± 0.6 % |

| Bending module: | 2910 ± 216 MPa |

| Bending force: | 70 ± 5 MPa |

| Impact Force: | 41.2 ± 2.6 kJ/m² |

Printing tips

– Bambu PETG-CF needs proper drying before printing. Drying conditions: 65℃ for 8 hours. Store in dry environment after use. Dry before use if the material absorbs moisture. For more details, please refer to: filament drying instructions in WIKI.

– To get a stronger Z-fit, please set a higher fill density and do not use an open-frame printer or set fan rates too high to avoid excessive cooling.

– To get a glossier look, set lower speeds and relatively higher temperatures.

What’s in the box?

There are no reviews yet.