ABS – without spool – Bambu green – Bambu Lab

RFID for smart printing

All print parameters are embedded in the RFID, which can be read via our AMS (Automatic Material System).

Load and print! No more tedious setup steps.

Printing tips

– Sharp and unpleasant odours may be emitted during printing. Make sure the printer is placed in a well-ventilated area.

– It is recommended to dry it before use to obtain a higher quality print.

The recommended drying condition is 80℃ for 8 hours in a shock dryer or 100℃ for 12 hours on the printer’s heating bed. For more details, please see: thread drying in WIKI.

– ABS is prone to distortion when printing a pattern of large size and/or high fill density. To avoid distortion:

1) Printing too large size and/or high density pattern is not recommended

2) Use enclosed printers and make sure the build plate is properly glued before printing.

3) Set a lower print speed and a higher heating field temperature. For more details, please see: common print quality problems and solutions on WIKI.

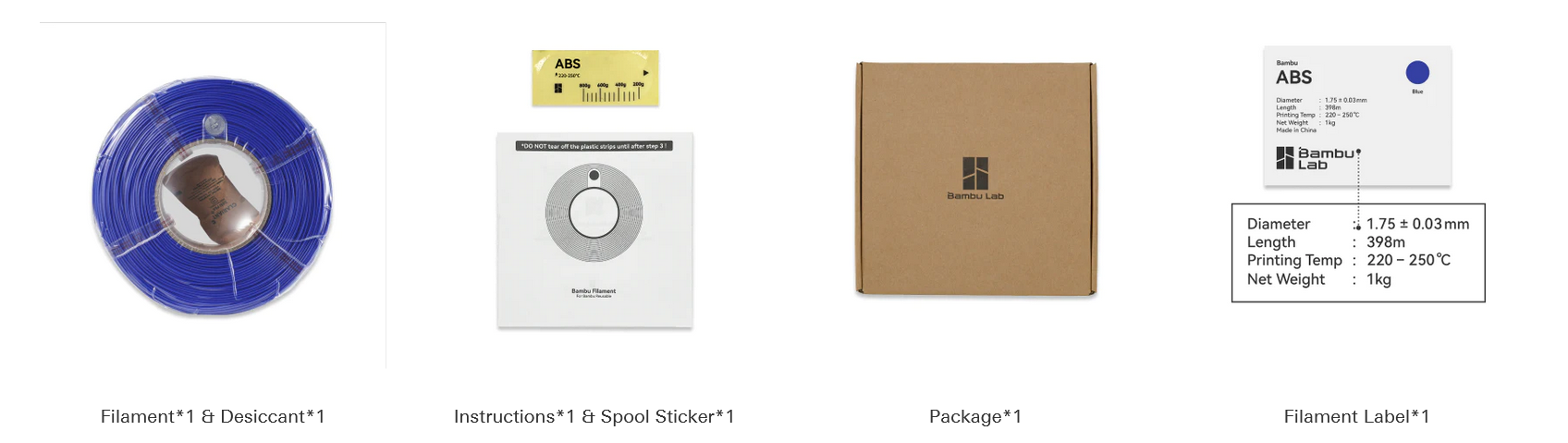

What’s in the box:

Print your own spool now

Bambu Lab’s 3D printer comes with a spool model. Print part 1 and 2 of the spool from the embedded files!

2.If you do not have the spool model in the printer,

please click here to download.

Spool printing instructions

When you’re done printing, you’ll have a wide part (1x), a narrow part (1x), and an intermediate pad (2x).

Find the locator (small block on the wide part). Align it with the notch on the inner ring of the filament pulley. Insert the wide part into the thread roll.

Step 1. Insert the narrow piece and align the groove of each piece inside the spool until it is firmly inserted into the wide piece.

Step 2. Once firmly inserted into the wide part, turn the narrow part clockwise until it slides into place and you hear it lock.

Step 1. Make sure the spacer pad is installed inside the spool (under the triangle).

Step 2. Tear and remove the plastic strips.

There are no reviews yet.