ABS – White – without spool – Bambu Lab

Features

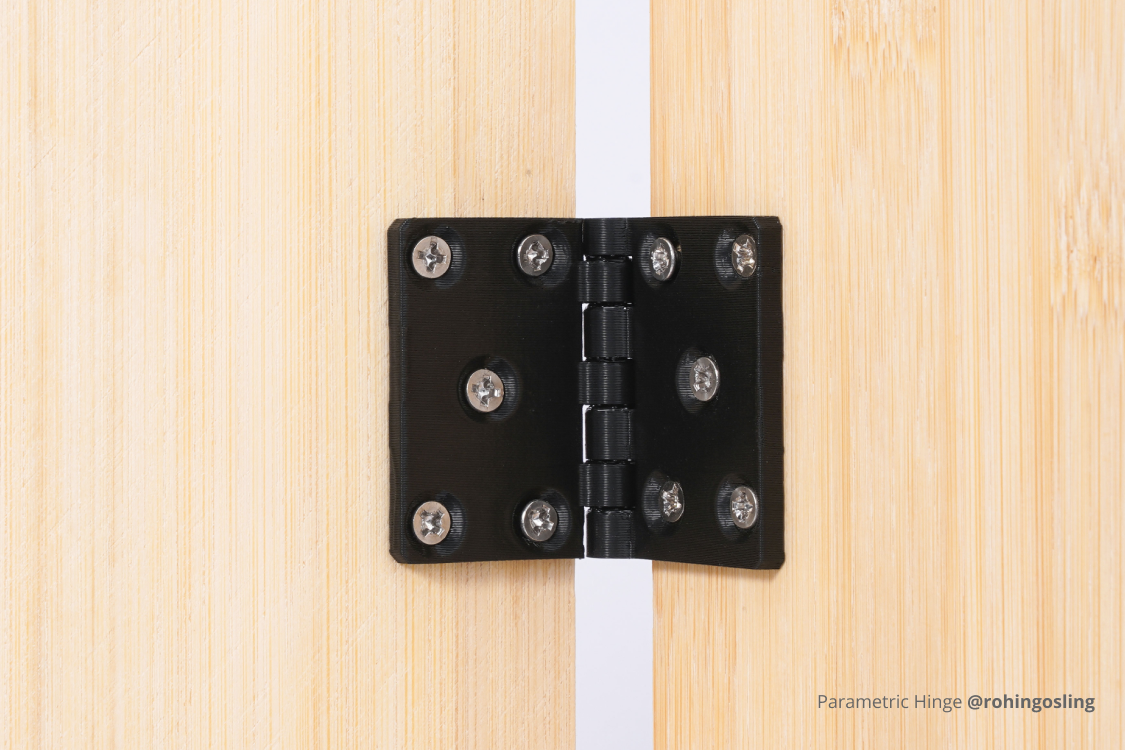

- Robust and durable

- Good resistance to heat and freezing

- Diameter: 1.75 mm +/- 0.03 mm

- Without roll

- Compatible with AMS

- AMS lite is NOT compatible

- Printer in housing required

Bambu ABS

Bambu ABS is a reliable 3D printing material known for its exceptional stability, durability and high impact resistance. This filament also features excellent heat resistance, making it ideal for projects involving moderate temperatures. With its versatile properties, Bambu ABS filament is an excellent choice for a wide range of 3D printing applications.

Strong and durable

As one of the most widely used filaments, Bambu ABS has excellent mechanical properties that make it stronger than ordinary PLA and PETG. It is ideal for creating functional parts, prototypes and standard engineering components, ensuring long life and reliability.

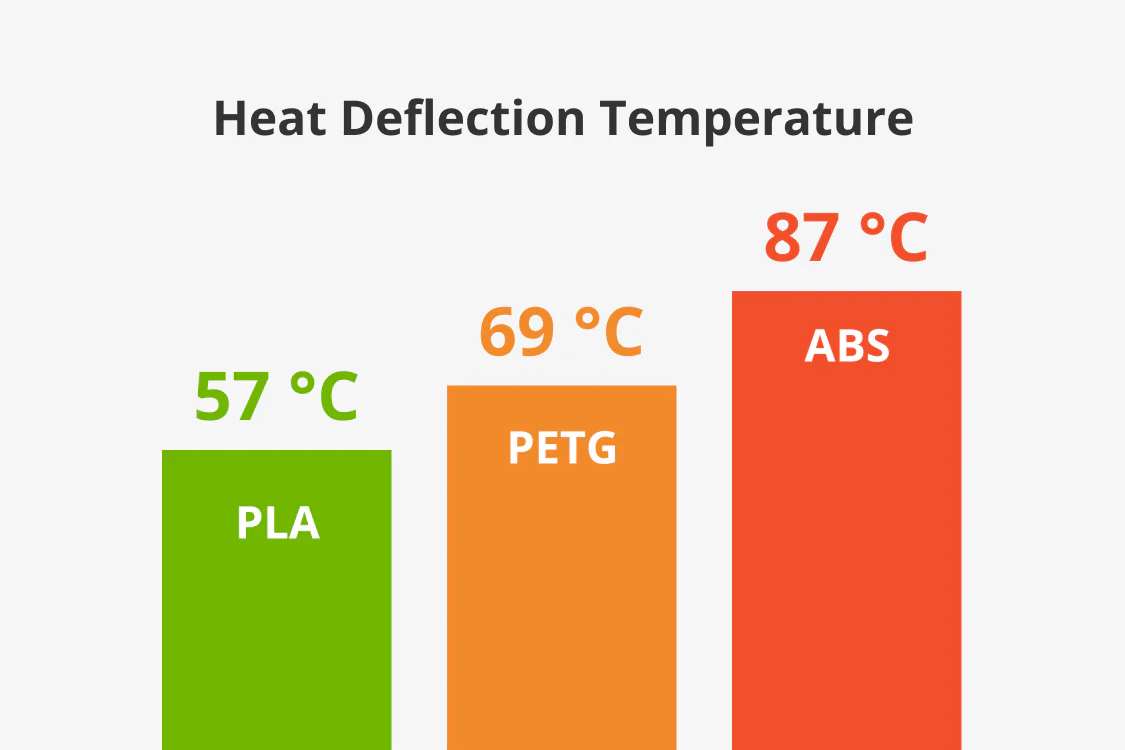

The Bambu ABS fibre offers outstanding heat resistance (heating deformation temperature: 87 °C) combined with excellent mechanical properties. This makes it an outstanding choice for everyday functional parts that require resistance to high temperatures.

Waterproof

Featuring excellent water resistance, Bambu ABS provides relatively long-lasting durability when used in wet environments.

Bambu ABS is extremely robust and its footprints can withstand multiple impacts, collisions and falls. It shows good impact resistance even at low temperatures.

Compatibility of accessories

| Recommended |

Not recommended |

|

| Backing: |

Smooth or textured backing

|

Cool pad SuperTack

|

| Hotend: | All sizes and materials | / |

| Glue | Bambu Liquid Glue

EcoFixy Glue Glue Stick |

/ |

RFID for smart printing

All print parameters are embedded in the RFID, which can be read via our AMS (Automatic Material System).

Load and print! No more tedious setup steps.

| Recommended print settings | |

| Drying settings (shock drying oven): | 80 °C,8 h. |

| Printing and maintaining the humidity of the container: | < 20% RH

(Sealed, with desiccant) |

| Nozzle temperature: | 240 – 270 °C |

| Bed temperature (with adhesive): | 80 – 100 °C |

| Print speed: | < 300 mm/s |

| Physical properties | |

| Density: | 1.05 g/cm³ |

| Vicat softening temperature: | 94 °C |

| Heat deflection temperature: | 87 °C |

| Melting temperature: | 200 °C |

| Melting index: | 34.2 ± 3.8 g/10 min. |

| Mechanical properties | |

| Tensile strength: | 33 ± 3 MPa |

| Fracture extension rate: | 10.5 ± 1.0 % |

| Bending module: | 1880 ± 110 MPa |

| Bending force: | 62 ± 4 MPa |

| Impact Force: | 39 ± 3.6 kJ/m² |

Tips when printing

Sharp and unpleasant odours may be emitted during printing. Make sure the printer is placed in a well-ventilated area.

– Drying conditions: 80℃ for 8 hours. After use, store in a dry environment. Dry before use if the material absorbs moisture. For more details, please refer to: drying instructions for threads in WIKI.

– ABS is prone to distortion when printing a pattern with a large size and/or high fill density. To avoid distortion: 1) It is not recommended to print too large a size and/or a pattern with a high fill density. 2) Use indoor printers and make sure the build plate is properly adhered before printing. 3) Set a lower print speed and higher heater panel temperature. For more details, please see: common print quality problems and solutions on WIKI.

There are no reviews yet.